Piping Material Specification |

Standard No.... Doc. No....

Issue Date:.. Dec, 20198 of 15

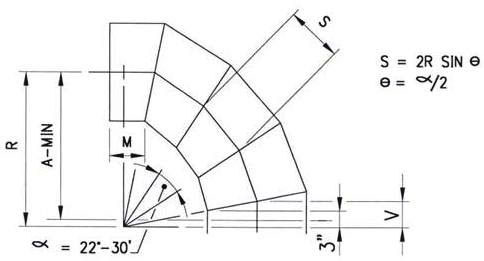

Four Weld 90° Long Radius Miter Elbow

| DIA Inches |

A Min. | R Radius |

S Inches |

M |

| 30 | 42w | 45 | 17p | |

| 32 | 44s | 48 | 18s | |

| 34 | 47r | 51 | 19f | |

| 36 | 49f | 54 | 21w | |

| 38 | 52i | 57 | 22r | |

| 40 | 55w | 60 | 23i | |

| 42 | 57s | 63 | 24p | 8r |

| 44 | 60r | 66 | 25s | |

| 46 | 62f | 69 | 27 | |

| 48 | 65i | 72 | 28i | 9p |

| 50 | 68w | 75 | 29r | |

| 52 | 70s | 78 | 30i | |

| 54 | 73r | 81 | 31p | 10f |

| 56 | 75f | 84 | 32f | |

| 58 | 78i | 87 | 34 | |

| 60 | 81w | 90 | 35w | |

| 62 | 83s | 93 | 36y | |

| 64 | 86y | 96 | 37i | |

| 66 | 88f | 99 | 38p | |

| 68 | 91i | 102 | 39f | |

| 70 | 94w | 105 | 41 | |

| 72 | 96s | 108 | 42r | |

| 78 | 104i | 117 | 45s | 15r |

| 84 | 112y | 126 | 49i | |

| 86 | 115 | 129 | 50y |

Notes..

- All dimensions are given in Inches.

- Welding shall be in accordance with the job specifications.

- These Miter elbows are to be used when authorized by the piping spec's.

- Use "A" dimension only where necessary to meet close clearance requirements or when connecting to flange or fitting.

- Material shall be as specified in the job piping materials specification class.

- "M" dimension does not include taper bore length.

- The "M" dimension must be calculated for Miter elbows other than 78in, 54in, 48in and 42in.

Other Pages

- Table of contents

- Scope, codes, standards and references

- General and specific requirements

- Abbreviations for piping specifications

- Valve tag numbering

- Standard installation detail - Utility Station

- Special fabricated larger diameter reducers

- Four weld 90° LR Miter elbow

- Two weld 45° LR Miter elbow

- Perforated temporary conical strainers

- T-Type strainers

- Drip ring

- Product sampler cooler

- Tolerances for pipe fabrication

- Line Blinds NPS 1/2 - NPS 60