Generic Marking Standards and Requirements

Component Identification

The ASME B31.3 Code requires random examination of materials and components to ensure conformance to listed specifications and standards. B31.3 also requires these materials to be free from defects. Component standards and specifications have various marking requirements.

MSS SP-25 standard

MSS SP-25 is the most commonly used marking standard. It contains a variety of specific marking requirements that are too lengthy to list in this appendix; please refer to it when necessary to confirm the markings on a component.

Title and Requirements

Standard Marking System for Valves, Fittings, Flanges and Unions

- Manufacturer's Name or Trademark

- Rating Designation

- Material Designation

- Melt Designation - as required by specification

- Valve Trim Identification - valves only when required

- Size Designation

- Identification of Threaded Ends

- Ring-Joint Facing Identification

- Permissible Omission of Markings

Specific Marking Requirements

- Marking Requirements for Flanges, Flanged Fittings, and Flanged Unions

- Marking Requirements for Threaded Fittings and Union Nuts

- Marking Requirements for Welding and Solder Joint Fittings and Unions

- Marking Requirements for Non-Ferrous Valves

- Marking Requirements for Cast Iron Valves

- Marking Requirements for Ductile Iron Valves

- Marking Requirements for Steel Valves

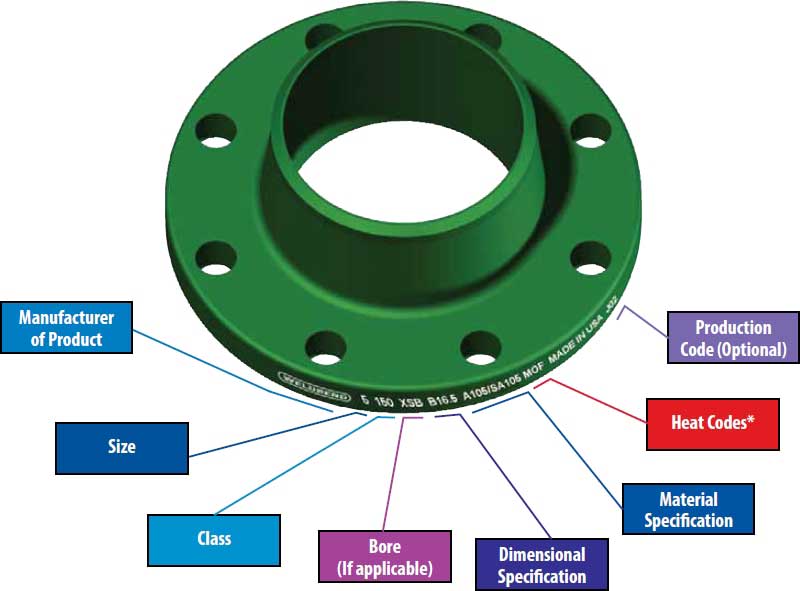

Marking Requirements Flanges (some examples)

Name The manufacturer’s name or trademark shall be applied.

Material shall be identified in the following way..

(a) Cast flanges and flanged fittings shall be marked with the ASTM specification,2 grade identification symbol (letters and numbers), and the melt number or melt identification.

(b) Plate flanges, forged flanges, and flanged fittings shall be marked with the ASTM specification number and grade identification symbol.

(c) A manufacturer may supplement these mandatory material indications with his trade designation for the material grade, but confusion of symbols shall be avoided.

(d) For flanges and flanged fittings manufactured from material that meets the requirements of more than one specification or grade.

Rating Designation The flange or flanged fitting shall be marked with the number that corresponds to its pressure rating class designation (i.e., 150, 300, 400, 600, 900, 1500, or 2500).

Conformance The designation B16 or B16.5 shall be applied to the flange or flanged fitting, preferably located adjacent to the class designation, to indicate conformance to this Standard. The use of the prefix ASME is optional.

Temperature Temperature markings are not required on flanges or flanged fittings; however, if marked, the temperature shall be shown with its corresponding tabulated pressure rating for the material.

Size The NPS designation shall be marked on flanges and flanged fittings. Reducing flanges and reducing flanged fittings shall be marked with the applicable NPS designations.

Ring Joint Flanges The edge (periphery) of each ring joint flange shall be marked with the letter R and the corresponding ring groove number.

Multiple Material Marking Material for components that meet the requirements for more than one specification or grade of a specification listed in Table 1A may, at the manufacturer’s option, be marked with more than one of the applicable specification or grade symbols. These identification markings shall be placed so as to avoid confusion in identification. The multiple marking shall be in accordance with the guidelines set out in ASME Boiler and Pressure Vessel Code, Section II, Part D, Mandatory Appendix 7.

Image is owned by.. www.weldbend.com

Image is owned by.. www.weldbend.comMarking of Steel Flanges

Marking Requirements Steel Pipe (some examples)

ASTM A53

Pipe, Steel, Black and Hot-Dipped, Zinc Coated, Welded and Seamless

- Name of Brand of Manufacturer

- Kind of Pipe (e.g. ERW B, XS)

- Specification Number

- Length

ASTM A106

Seamless Carbon Steel Pipe for High-Temperature Service

- Marking requirements of A530/A530M

- Heat Number

- Hydro/NDE Marking

- "S" for supplementary requirements as specified (stress-relieved annealed tubes, air underwater pressure test, and stabilizing heat treatment)

- Length

- Schedule Number

- Weight on NPS 4 and larger

ASTM A312

Standard Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

- Marking requirements of A530/A530M

- Manufacturer's Private Identifying Mark

- Seamless or Welded

ASTM A530/A530A

Standard Specification for General Requirements for Specialized Carbon and Alloy Steel Pipe

- Manufacturer's Name

- Specification Grade

Marking of Steel Pipes

Marking of Steel Pipes

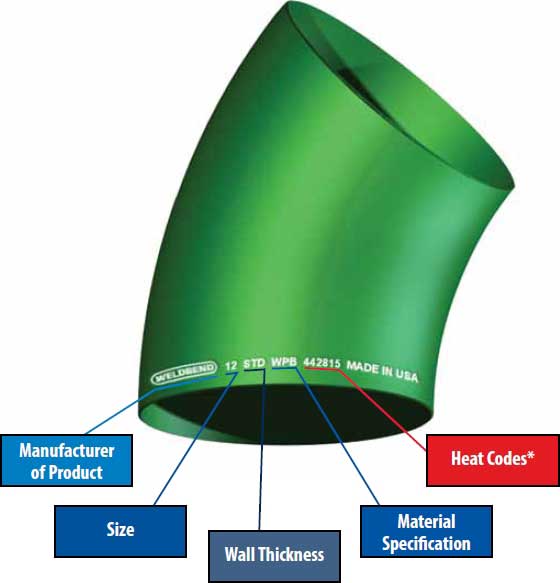

Marking Requirements Fittings (some examples)

ASME B16.9

Factory-Made Wrought Steel Buttwelding Fittings

- Manufacturer's Name or Trademark

- Material and Product Identification (ASTM or ASME grade symbol)

- "WP" in grade symbol

- Schedule number or nominal wall thickness

- NPS

ASME B16.11

Forged Fittings, Socket Welding and Threaded

- Manufacturer's Name or Trademark

- Material identification in accordance with the appropriate ASTM

- Product conformance symbol, either "WP" or "B16"

- Class designation - 2000, 3000, 6000, or 9000

Where size and shape do not permit all of the above markings, they may be omitted in the reverse order given above.

MSS SP-43

Wrought Stainless Steel Butt-Welding Fittings

- Manufacturer's Name or Trademark

- "CR" followed by ASTM or AISI material identification symbol

- Schedule number or nominal wall thickness designation

- Size

Image is owned by.. www.weldbend.com

Marking of Butt Weld Fittings

Marking Requirements Valves (some examples)

API Standard 602

Compact Steel Gate Valves - Flanged, Threaded, Welded, and Extended Body Ends

- Valves shall be marked in accordance with the requirements of ASME B16.34

- Each valve shall have a corrosion-resistant metal identification plate with the following information..

- Manufacturer

- Manufacturer's model, type, or figure number

- Size

- Applicable pressure rating at 100F

- Body material

- Trim material - Valve bodies shall be marked as follows..

- Threaded-end or Socket Welding-end valves - 800 or 1500

- Flanged-end valves - 150, 300, 600, or 1500

- Buttwelding-end valves - 150, 300, 600, 800, or 1500

ASME B16.34

Valves - Flanged, Threaded and Welded End

- Manufacturer's Name or Trademark

- Valve Body Material Cast Valves - Heat Number and Material Grade Forged or Fabricated Valves - ASTM Specification and Grade

- Rating

- Size

- Where size and shape do not permit all of the above markings, they may be omitted in the reverse order given above

- For all valves, the identification plate shall show the applicable pressure rating at 100F and other markings required by MSS SP-25

Marking Requirements Fasteners (some examples)

ASTM 193

Specification for Alloy-Steel and Stainless Steel Bolting Materials for High-Temperature Service

- Grade or manufacturer's identification symbols shall be applied to one end of studs 3/8" in diameter and larger ands to the heads of bolts 1/4" in diameter and larger

ASTM 194

Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure and High-Temperature Service

- Manufacturer's identification mark. 2.Grade and process of manufacture (e.g. 8F indicates nuts that are hot-forged or cold-forged)

Types of Marking Techniques

There are several techniques in order to mark a pipe, flange, fitting, etc., such as..

Die Stamping

Process in which an engraved die is used to cut and stamp (leave an impression)

Paint Stencilling

Produces an image or pattern by applying pigment to a surface over an intermediate object with gaps in it which create the pattern or image by only allowing the pigment to reach some parts of the surface.

Other techniques are Roll stamping, Ink Printing, Laser Printing etc.

Related Post(s)

ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by "Grade"...