|

PTFE envelope flange gaskets |

A PTFE envelope gasket is a composite gasket, and consists of an envelope of PTFE with an insert. The envelope gasket is mainly used as a flange gasket in applications where high chemical and pressure resistance is required.

Because of the cold flow affinity of unfilled PTFE, PTFE composites are primarily used because PTFE wrapped gaskets are more resistant to stress relaxation.

Due to their high chemical resistance and excellent sealing properties, PTFE-wrapped gaskets have proven excellent in use at fluctuating pressures and temperatures from -195 °C to +250 °C.

Applications of PTFE envelope gaskets

In chemically aggressive environments, where contamination of the medium is not allowed, it is complicated to apply a standard gasket. Here PTFE envelope gaskets are applied as flange gaskets, for example in the (petro)chemical industry and in the process industry.

Envelope gaskets are also ideal for application in the food industry. PTFE is physiologically inert and can be used in direct contact with food.

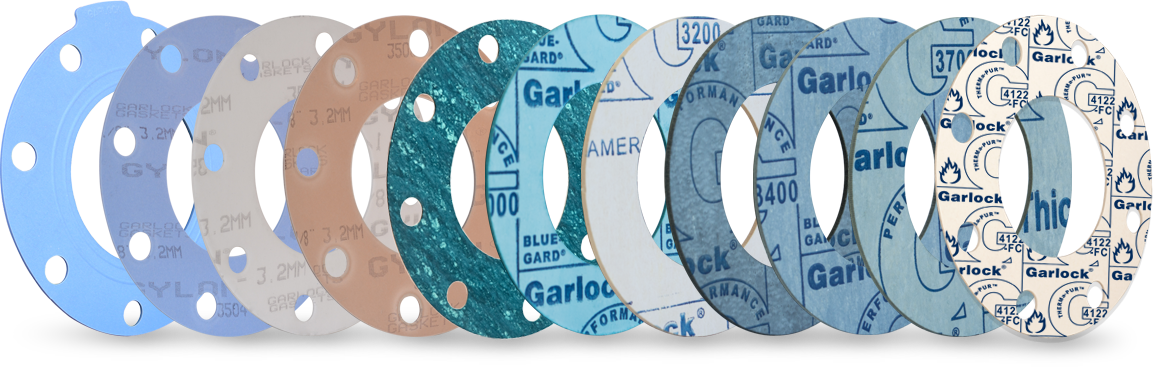

Types and profiles of PTFE envelope gaskets

| U-envelope | For average and high pressures. |

| C-envelope with diffusion stop | Specially designed gasket with a so-called 3 mm thick diffusion stop. |

| Double U-envelope | Suitable for high pressures. A sealed gasket with a linear upper side. Is applied in places where the medium may contact the upper side of the seal. |

| Donut envelope | Suitable for high pressures. A sealed gasket with a round upper side. Is applied in places where the medium may contact the upper side of the seal. |

| C-envelope | For average and high pressures, but is suitable for a more flexible inlay (for example rubber). |

| Y- or V-envelope | A low cost solution for lower pressures. The inlay material is up to 2 mm thick. |

There are many more types and profiles available, and the above versions are only examples of commonly used envelope gaskets....

Reference(s):

| klinger-awschultze.de | |

| ridderflex.com |

| STD | FF | ||||

| NPS | OD x ID | OD x ID | NBH | DBH | PCD |

| 1/2 | 48 x 21 | 89 x 21 | 4 | 16 | 60 |

| 1/2 | 48 x 21 | 89 x 21 | 4 | 16 | 60 |

| 3/4 | 57 x 27 | 95 x 27 | 4 | 16 | 70 |

| 1 | 67 x 33 | 108 x 33 | 4 | 16 | 79 |

| 1.1/4 | 76 x 42 | 117 x 42 | 4 | 16 | 89 |

| 1.1/2 | 86 x 48 | 127 x 48 | 4 | 16 | 98 |

| 2 | 105 x 60 | 152 x 60 | 4 | 19 | 121 |

| 2.1/2 | 124 x 73 | 178 x 73 | 4 | 19 | 140 |

| 3 | 137 x 89 | 191 x 89 | 4 | 19 | 152 |

| 3.1/2 | 162 x 102 | 216 x 102 | 8 | 19 | 178 |

| 4 | 175 x 114 | 229 x 114 | 8 | 19 | 191 |

| 5 | 197 x 141 | 254 x 141 | 8 | 22 | 216 |

| 6 | 222 x 168 | 279 x 168 | 8 | 22 | 241 |

| 8 | 279 x 219 | 343 x 219 | 8 | 25 | 298 |

| 10 | 340 x 273 | 406 x 273 | 12 | 25 | 362 |

| 12 | 410 x 324 | 483 x 324 | 12 | 29 | 432 |

| 14 | 451 x 356 | 533 x 356 | 14 | 29 | 476 |

| 16 | 514 x 406 | 597 x 406 | 16 | 32 | 540 |

| 18 | 549 x 457 | 635 x 457 | 16 | 32 | 578 |

| 20 | 606 x 508 | 699 x 508 | 20 | 32 | 635 |

| 24 | 718 x 610 | 813 x 610 | 20 | 35 | 749 |

| STD | FF | ||||

| NPS | OD x ID | OD x ID | NBH | DBH | PCD |

| 1/2 | 54 x 21 | 95 x 21 | 4 | 16 | 67 |

| 3/4 | 67 x 27 | 117 x 27 | 4 | 19 | 83 |

| 1 | 77 x 33 | 124 x 33 | 4 | 19 | 89 |

| 1.1/4 | 83 x 42 | 133 x 42 | 4 | 19 | 98 |

| 1.1/2 | 95 x 48 | 156 x 48 | 4 | 22 | 114 |

| 2 | 111 x 60 | 165 x 60 | 8 | 19 | 127 |

| 2.1/2 | 130 x 73 | 191 x 73 | 8 | 22 | 149 |

| 3 | 149 x 89 | 210 x 89 | 8 | 22 | 168 |

| 3.1/2 | 165 x 102 | 229 x 102 | 8 | 22 | 184 |

| 4 | 181 x 114 | 254 x 114 | 8 | 22 | 200 |

| 5 | 216 x 141 | 279 x 141 | 8 | 22 | 235 |

| 6 | 251 x 168 | 318 x 168 | 12 | 22 | 270 |

| 8 | 308 x 219 | 381 x 219 | 12 | 29 | 330 |

| 10 | 362 x 273 | 445 x 273 | 16 | 29 | 387 |

| 12 | 422 x 324 | 521 x 324 | 16 | 25 | 451 |

| 14 | 486 x 356 | 584 x 356 | 20 | 32 | 514 |

| 16 | 540 x 406 | 648 x 406 | 20 | 35 | 572 |

| 18 | 597 x 457 | 711 x 457 | 24 | 35 | 629 |

| 20 | 654 x 508 | 775 x 508 | 24 | 35 | 686 |

| 24 | 775 x 610 | 914 x 610 | 24 | 41 | 813 |

| STD | FF | ||||

| NPS | OD x ID | OD x ID | NBH | DBH | PCD |

| 1/2 | 54 x 21 | 95 x 21 | 4 | 16 | 67 |

| 3/4 | 67 x 27 | 117 x 27 | 4 | 19 | 83 |

| 1 | 77 x 33 | 124 x 33 | 4 | 19 | 89 |

| 1.1/4 | 83 x 42 | 133 x 42 | 4 | 19 | 98 |

| 1.1/2 | 95 x 48 | 156 x 48 | 4 | 22 | 114 |

| 2 | 111 x 60 | 165 x 60 | 8 | 19 | 127 |

| 2.1/2 | 130 x 73 | 191 x 73 | 8 | 22 | 149 |

| 3 | 149 x 89 | 210 x 89 | 8 | 22 | 168 |

| 3.1/2 | 162 x 102 | 229 x 102 | 8 | 25 | 184 |

| 4 | 194 x 114 | 273 x 114 | 8 | 25 | 216 |

| 5 | 241 x 141 | 330 x 141 | 8 | 29 | 267 |

| 6 | 267 x 168 | 356 x 168 | 12 | 29 | 292 |

| 8 | 321 x 219 | 419 x 219 | 12 | 32 | 349 |

| 10 | 508 x 273 | 445 x 273 | 16 | 35 | 432 |

| 12 | 559 x 324 | 521 x 324 | 20 | 35 | 489 |

| 14 | 603 x 356 | 584 x 356 | 20 | 38 | 527 |

| 16 | 686 x 406 | 648 x 406 | 20 | 41 | 603 |

| 18 | 743 x 457 | 711 x 457 | 20 | 44 | 654 |

| 20 | 813 x 508 | 775 x 508 | 24 | 44 | 724 |

| 24 | 791 x 610 | 940 x 610 | 24 | 51 | 838 |

Related Post(s)

Flange gaskets are used to create a static seal between two flanges faces, at various operating conditions, with varied pressure and temperature ratings...