Gaskets for Chlorine service

Chlorine is a highly aggressive oxidising agent that reacts with many metals and organic compounds. Chemical compatibility and resistance to chlorine are important criteria when selecting a chlorine gasket material.

Service conditions, including contact with dry or wet chlorine, should be considered when assessing chemical resistance.

Physical properties

Since all gasket materials are porous, a compressive force sufficient to reduce this porosity must be applied. If the initial load is insufficient or if the compression of the gasket decreases, the system pressure may push the trapped fluid into or around the gasket due to porosity, leading to degradation, leakage or deflation of the gasket.

Material factors such as gasket creep and bolt relaxation, and especially installation or flange fitting practices can affect gasket compression. When choosing a gasket material, consider compressibility, recovery, creep relaxation, sealability, tensile strength and required tension to seal.

Installation and maintenance

Proper installation and maintenance of gaskets is an essential part of a leak-free chlorine system. During installation, the correct pressure force should be applied to create sufficient friction between the gasket and the flange, and sufficient pressure applied to reduce the porosity of the gasket material to obtain the correct seal. It is imperative that personnel are trained to install gaskets correctly. When installing a gasket, the recommended procedures of the manufacturer, equipment supplier and/or end-user should be followed. These procedures usually include the following..

- Inspect the gasket to verify that it is the correct size, material, and type for the intended service, and that it is clean and undamaged.

- Inspect the flanges to verify that they are properly aligned, clean, and undamaged.

- Examine bolts or studs, nuts, and washers for defects such as burrs or cracks, rust, and replace as needed.

- Avoid lubricating the gasket. Lubricants can attack some gaskets and can cause gaskets to blow out by reducing the friction between the gasket and the flanges.

- Use chlorine compatible lubricants on nut threads and facings, and bolts to reduce friction between the flange fasteners and to create a consistent and correct bolt load.

- Tighten the bolts to the gasket and/or flange manufacturer's specifications, taking care to use the recommended cross bolt pattern in multiple steps of increasing torque, until the final torque requirements are achieved. To prevent damage it is important not to over torque. This is particularly important in wet chlorine service when plastic piping is used.

- External factors including vibration, temperature cycling and pressure spikes can cause the loss of compressive load. If recommended by the gasket manufacturer, re-torque the bolts, per proper procedure, after letting the gasket set and after the gasket has been in service for a short period of time.

Training of personnel installing gaskets is an essential part of leak-free chlorine system operation. Good procedures and a well-trained team improve the integrity of the chlorine piping system.

Gasket materials in WET chlorine plants

| EPDM gasket |  |

| Expanded PTFE gasket |  |

| Filled PTFE gasket sheet |  |

| Microcellular PTFE gasket |  |

| Viton A Fluoroelastomer, soft |  |

| SBR (Styrene butadiene rubber) |  |

| Virgin PTFE, (unfilled and unexpanded) |  |

| Ethylene propylene high polymer content (EPDM) elastomer |  |

Gasket materials in DRY chlorine plants named by brand

Related Post(s)

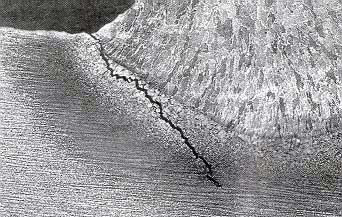

Pipelines and pressure vessels made of carbon steel and low-alloy steel can exhibit hydrogen-induced cracking (Hydrogen Induced Cracking, HIC) in a wet environment with hydrogen sulfide in the oil and gas industry...