What is Hot forging?

As a major metal fabrication, forging is a metal forming technique that uses localized forces of compression. Forgings have undergone major changes that lead to more efficient, faster and more durable processes. Today’s forging is usually done using electric, hydraulic or compressed air driven forging presses or hammer tools.

Hot forging involves heating a workpiece to about 75% of its melting temperature. This reduces the yield stress and energy required to form the metal, effectively increasing the production rate (or strain rate). Hot forging helps make the metal easier to form and less likely to break.

Iron and its alloys are almost always hot forged for two main reasons..

- As the work hardens, hard materials (such as steel and iron) will be harder to machine, and

- it is more economical to hot forge metals such as steel and then follow with heat treatment processes, since metals such as steel can be strengthened through other processes (and not necessarily just cold working processes).

While other materials must be strengthened by the forging process itself, materials such as most titanium and aluminum alloys can be hot forged and then hardened.

Average temperatures for hot forging includes..

- Aluminum (Al) Alloys - 360° (680°F) to 520°C (968°F)

- Copper (Cu) Alloys - 700°C (1 292°F) - 800°C (1 472°F)

- Steel – up to 1 150°C (2 102°F)

In hot forging, the temperature is above the recrystallization point of the metal formed. Because it is a process in which metals are plastically deformed above their recrystallization temperature, these high temperatures are necessary to prevent strain hardening during the deformation.

In this process, the metal is usually heated (above its recrystallization point) after which it is struck into a die - depending on requirements, this die may also be heated. Because the metal is hot, it "moves" easily and manufacturers can make more elaborate shapes than in cold forging.

For superalloys (which have low malleability), processes such as isothermal forging - where deformation takes place in a controlled atmosphere - are used to prevent oxidation.

Isothermal forging, also known as hot die forging, is a hot working process in which the workpiece is maintained at its maximum elevated temperature throughout the forming process.

This temperature is maintained by heating the die - it will be at the temperature of, or slightly below, the elevated temperature of the workpiece. The forces exerted by this die shape the workpiece and, because the die is also at an elevated temperature, cooling of the workpiece between the die-work interface is eliminated. This, in turn, results in an improvement in the flow properties of the metal (workpiece).

It should be noted that isothermal forging can also be performed in vacuum.

Image..mfindllc.com

Image..mfindllc.com

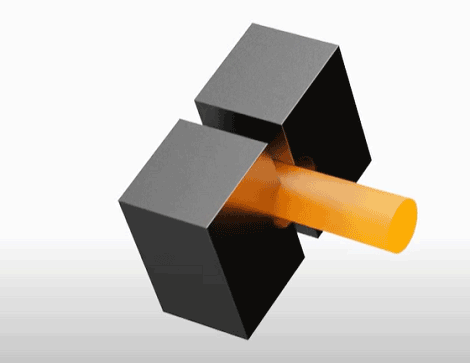

Hot forging dies

The dies used in hot forging undergo heavy thermal cycling and mechanical stress. This in turn affects the life of the die, as the die is open to..

- Coarse cracking

- Plastic deformation

- Thermal fatigue cracking

- Wear

Depending on the type of forging operation, the material and the size of the part being formed, to name but a few, forging dies must have the following properties and characteristics..

- A sufficient hardness and the ability to maintain this hardness at elevated temperatures.

- A sufficient hardness and resistance to fatigue.

- A good ductility and toughness in all directions at both high and low temperatures.

- Higher levels of both hot hardness and hot tensile strength.

The Benefits of Hot Forging

Hot forging, which is often used for the types of parts that affect engineering applications, is also a recommended process for deforming metals with a high deformation ratio.

The advantages of hot forging includes..

- An increased ductility.

- Because of the decrease in yield strength, it takes less energy (or force) to work with the material.

- During hot forging and subsequent deformation, pores can reduce (in size) or close completely.

- Because the elevated temperatures increase diffusion it is possible, in turn, to reduce or remove chemical inhomogeneity.

- In hot forging steel, the weak and ductile FCC (face-centered cubic) austenite is deformed instead of the strong BCC (body-centered cubic) ferrite – which would deform at lower forging temperatures.

The Disadvantages of Hot Forging

- Hot working, as all metal forming processes, also has a set of disadvantages. These disadvantages include..

- The result of a less precise tolerance caused by warping and thermal contraction. This is caused in instances where uneven cooling is present.

- There is the possibility that the grain structure may vary throughout the metal.

- With hot working, there is also the possibility of an undesirable reaction between the metal being forged and the surrounding atmosphere.

Hot Forging Animation