Flux-Cored Arc Welding

Flux-Cored Arc Welding is a welding method that is somewhat unique compared to Metal Inert Gas welding (MIG). What mainly distinguishes FCAW from MIG welding is the type of wire electrode used and the way the molten metal is protected from the atmosphere.

The Gas metal arc welding (GMAW) MIG welding process uses a continuous electrode with solid wire, usually made of mild steel. An external gas supply is required to create a shield that protects the weld pool. This is usually provided by a high-pressure gas cylinder.

Like MIG, FCAW requires electricity, filler material and a way to shield the molten metal from the air.

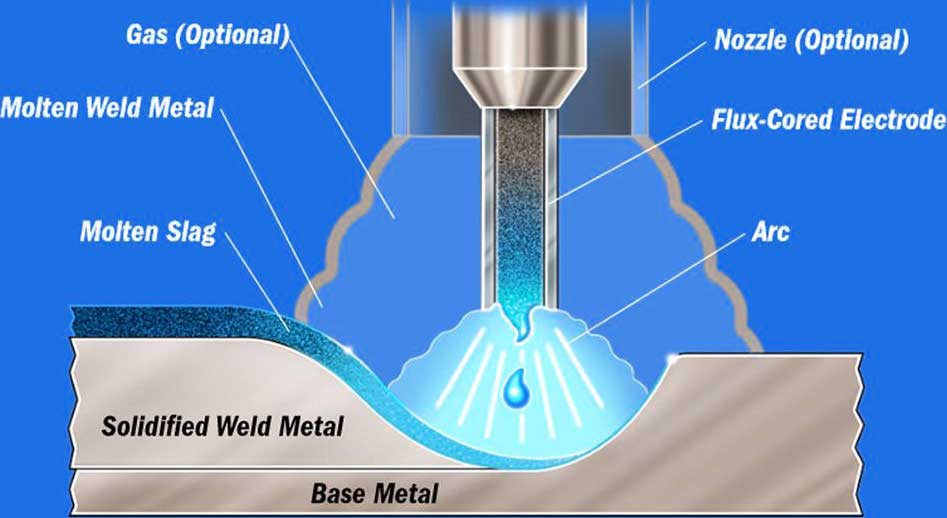

Unlike the MIG process, the flux-cored method uses a wire that contains an inner core made of materials that produce flux and shielding gases when burned by the heat of the welding arc.

This type of wire does not require an external gas supply because the wire has internal shielding properties.

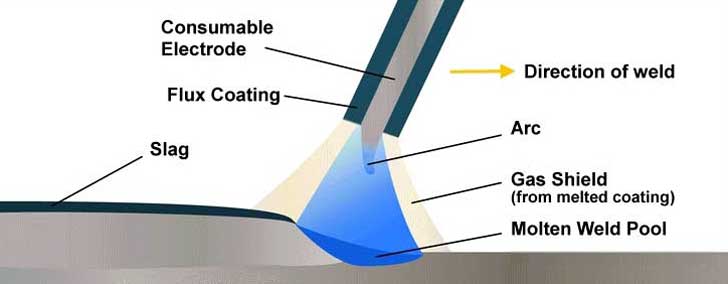

Images of FCAW and GMAW gas nozzles and electrodes. With FCAW, shielding gas is not always used. If no shielding gas is used, no nozzle is needed.

Using the FCAW method

For thicker material, Flux-Cored Arc Welding works better than MIG welding. In fact, FCAW is only recommended for materials no thinner than 20 gauge. When using the FCAW process on thicker metals, a good, strong weld can be made in one pass.

Because the filled wire produces its own shielding gas during the welding process, FCAW works much better outdoors than the MIG method. This internal shielding can even withstand strong winds. There is no need to bring a separate gas cylinder to the welding site, which makes FCAW more convenient.

One of the disadvantages of FCAW is that the welding arc creates spatter. As a result, the finished weld is covered with slag that may need to be removed.

To begin the welding process with the flux-drilled method, the welder first depresses the trigger, which continuously feeds the electrode to the weld seam. As the electrode passes through the wire feeder, it becomes electrically charged. When the wire reaches the metal joint, a short circuit occurs, causing the electrode to heat up and begin to melt.

As the wire electrode melts, the metal also begins to melt. Together, the melting electrode and the metal form a molten bath. The molten bath simultaneously melts the flux core of the electrode to create a protective shield from the environment and a slag that protects the weld from contamination.

Which metals work best with FCAW

Most non-ferrous exotic metals, including aluminum, cannot be welded with the flux cored method. However, flux cored welding works well on most carbon steels, nickel alloys, cast iron and some stainless steels.

Related Post(s)

The manual Metal Arc Process - Shielded metal arc welding (SMAW), or manual metal arc welding was first invented in Russia in 1888...