|

Health and safety in welding |

Welding is a hazardous workplace activity that exposes workers to health and safety risks. Welding safety measures are designed to protect workers from welding hazards.

Welding safety can be implemented by providing proper training, inspecting welding equipment, and ensuring workers are aware of safety measures before performing welding activities to minimize the risk of health and safety injuries.

Health Hazards

Welding processes pose several potential health hazards. The most common hazards are exposure to radiation, heat, noise, fumes and gases.

These potential hazards are briefly described below and some protective measures for the specific hazards are described.

Radiation

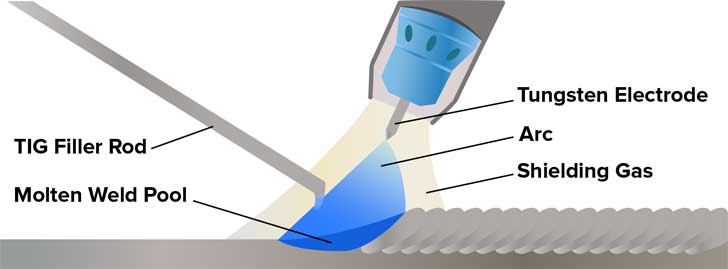

Radiation is a process by which energy is transferred through space or matter. There are two types of radiation associated with welding operations; ionizing and non-ionizing. Ionizing radiation is produced by the electron beam welding process and during the grinding (pointing) of toriated tungsten electrodes for the Gas Tungsten Arc Welding (GTAW) process.

To minimize exposure to ionizing radiation from the grinding dust, local exhaust ventilation and respirators should be used.

Non-ionizing radiation is the most common type of radiation produced by most types of welding and includes ultraviolet, infrared, and visible light. Eye injuries are the most common injury sustained by welders, as the eyes can be adversely affected by all three energy ranges (ultraviolet, infrared, and visible light).

The skin is essentially only sensitive to the effects of ultraviolet and infrared radiation, and warns us of infrared heat radiation by burning the skin. Severe erythema or "sunburn" of the skin may increase the risk of skin cancer with prolonged exposure.

It does not take long exposure to burn the eyes. The severity depends on the duration of exposure, the intensity of the light source, and the proximity of the eye to the source. Even short exposure to an intense source can cause burns. Inflammation (swelling of the cornea) and eye irritation, also known as flash burns, do not become noticeable for several hours.

Applying ice packs will usually relieve the pain, but if it persists, seek medical attention. Staring at the blue color of the arc can cause photochemical changes in the retina, resulting in permanent vision loss unless appropriate protective filters are used.

Eyes must be protected from burns, light, and heat. Safety glasses and welding shields provide good protection. Safety glasses with side shields protect against flying sparks and flying chips. It is important that all workers wear eye protection when near a welding operation to prevent arc burns. If a worker is exposed to ultraviolet light, burns can occur even though the light does not seem intense.

Ultraviolet (UV) radiation is generated by all arc welding processes. UV radiation can damage the cornea of the eye. Many arc welders are aware of the condition known as "welder's flash or arc flash", a feeling of sand in the eyes. The medical term for this condition is photokeratitis and photoconjunctivitis. The arc should never be viewed without eye protection.

Exposure of the skin to UV can also cause severe burns, often without warning. Skin and eye burns from UV exposure can be prevented by using proper clothing and eye protection. It is important that welders wear clothing that covers their exposed skin and use proper eye protection that meets filter lens shade requirements.

Heat

Most people know that metal at a "red heat" temperature can burn the skin. However, material can still cause damage at lower temperatures when it has lost its red heat. In welding operations, hot metal is always present and in some cases the metal is preheated to as much as 600 degrees Fahrenheit (315 degrees Celsius) to improve weldability. Physiological effects of heat include skin burns, hyperthermia, and heat stress when the body temperature rises to very high levels. Heat problems are usually controlled by a combination of engineering methods, work practices, and personal protective equipment.

Some of the most common methods include..

- Use cooling fans to increase airflow over the worker and increase evaporative heat loss. The airflow should be from one side over the worker for optimum control.

- Use mechanical air conditioning systems in conjunction with the make-up air system.

- Increase general exhaust ventilation at points of high heat generation

- Provide shielding between the welder and the source of radiant heat, such as a preheated work surface.

- Ensure that the welder can take regular breaks in a cooler area and has adequate access to cold drinking water.

Noise

Noise problems are not normally directly associated with welding operations, except for plasma arc or air carbon arc welding processes. Probably the most common operations that produce relatively high noise levels are plasma arc cutting and air carbon arc cutting. Other operations that are associated with many welding operations, such as chipping and grinding, are common sources of noise problems.

In many cases, excessive noise associated with welding operations cannot be reduced by engineering controls. Therefore, suitable hearing protection should be used and regular audiometric testing may be necessary to detect the onset of hearing loss.

Inhalation Hazards

One of the greatest health risks for welders is inhalation of fumes and gases. The degree of exposure is determined by the exposure time, concentration and nature of the contaminant in the breathing zone. Contamination is normally measured in milligrams per cubic meter (mg/m3) of air for particulate matter. For gases, parts per million (ppm) in air is sometimes used.

Fumes

Fumes are very fine solid particles that form by condensation from the gaseous state. Welding fumes consist of metals, metal oxides, and other compounds that volatilize from the base metal, electrode, or flux material. All welding processes produce fumes, but the amount can vary greatly depending on the process.

Welding fume particles are almost all less than one micrometer in diameter, so fumes are present during welding whether or not a smoke plume is visible. Because of their small size, fumes can penetrate deep into the respiratory tract and into the alveoli.

The presence of certain toxic metals in fumes can be a more important factor in determining the degree of hazard than the total amount of fumes. Metals such as manganese, chromium, nickel, cadmium, zinc, and copper may be present as small fractions of the total fume, but can be the greatest hazard on the job. The main sources of fumes are the electrode metal, flux material, and coatings on the base metal.

Long-term and repeated overexposure to these metals can potentially cause respiratory and/or neurological problems. Welding fumes are also classified as "possibly carcinogenic".

The rate of fume generation can be altered by voltage, arc length, current, electrode diameter, electrode polarity, shielding gas, base metal, fluxes, fillers, wire feed speed, humidity, and position of the weld. As voltage, arc length, current, wire feed speed, and humidity increase, more fume is generated. 30% more fume is generated by DC positive welding compared to DC negative or AC.

Gases

Gases are produced in all welding processes, and are produced by the decomposition of shielding gases and fluxes and by the interaction of ultraviolet light or high temperatures with atmospheric gases and the shielding gas.

Ozone, nitrogen oxides and carbon monoxide are the most common gases formed. Phosgene gas can be produced from chlorinated solvents that decompose in the welding arc.

Phosgene reacts with moisture in the lungs to form hydrochloric acid, which is extremely toxic. To prevent this, the use or storage of solvents near welding operations should be prohibited. At the concentrations normally encountered, these gases are not visible to the eye and, in the case of carbon monoxide, not detectable by smell.

The concentration of gases from welding can reach potentially toxic levels in confined spaces or in areas with little or no ventilation. However, there are ventilation regulations that address these exposures.

There are many work situations which increase the hazards of welding. Each must be carefully assessed as there may be additional hazards such as falls or asphyxiation. This is particularly true of work in confined spaces, where there is a very real risk of death and a critical assessment of the work must be made so that it can be carried out safely. There may be legal requirements in these situations and in most countries there is guidance literature available.

Related Post(s)

Gas tungsten arc welding (GTAW), also known as Tungsten Inert Gas (TIG) welding became an overnight success in the 1940s for joining magnesium and aluminium...