Pipeline vs Piping

In the oil and gas industry, you will find many similar terminologies, but with a wide variation in usage and functionality.

This article addresses the Piping and Pipeline confusion. If someone asks you what the difference is between Piping and Pipeline, chances are you'll be tempted to say they're similar. But let's clarify these fundamental differences between piping and pipeline terminology.

Definition of Pipline and Piping

A pipeline is a long chain of pipes, usually of large diameters, that can run underground, above ground and under water, such as a submarine pipeline, and are equipped with fittings such as valves and pumps to control the flow of large quantities of fluid over long distances.

Piping is a network of pipelines within a specified boundary or space in an oil and gas plant that also has valves and fittings to control the flow of fluid from one facility to another, but within the specified boundary of the plant as and when needed. When taking an online course in pipeline engineering, never skip these essential topics.

Pipelines also have a larger diameter so they can easily transport liquids or gases in bulk from one place to another, sometimes for thousands of miles. But Piping can range from 1/2inch to 80inch, depending on the design requirements of the facility to transport fluid, usually from one piece of equipment to another within the boundaries of the facility.

Piping

Design Codes and Standards

Pipeline standard ASME B31.4 prescribes requirements for the design, materials, construction, assembly, inspection, testing, operation, and maintenance of liquid pipeline systems between production fields or facilities, tank farms, above- or belowground storage facilities, natural gas processing plants, refineries, pump stations, ammonia plants, terminals (marine, rail, and truck), and other delivery and receiving points, as well as pipelines transporting liquids within pump stations, tank farms, and terminals associated with liquid pipeline systems.

Pipeline standard ASME B31.8 covers gas transmission and distribution piping systems, including gas pipelines, gas compressor stations, gas metering and regulation stations, gas mains, and service lines up to the outlet of the customer’s meter set assembly. It includes gas transmission and gathering pipelines, including appurtenances that are installed offshore for the purpose of transporting gas from production facilities to onshore locations; gas storage equipment of the closed pipe type that is fabricated or forged from pipe or fabricated from pipe and fittings; and gas storage lines.

Piping standard ASME B31.3 is the Process Piping standard and contains requirements for piping typically found in petroleum refineries; chemical, pharmaceutical, hydrogen, textile, paper and pulp, power generation, semiconductor, and cryogenic plants; and related processing plants and terminals. It covers materials and components, design, fabrication, assembly, erection, examination, inspection, and testing of piping.

Piping standard ASME B31.1 covers Power Piping and prescribes requirements for the design, materials, fabrication, erection, examination, testing, inspection, operation, and maintenance of piping systems typically found in electric power generating stations, industrial and institutional plants, geothermal heating systems, and central and district heating and cooling systems. It also covers boiler-external piping for power boilers and high-temperature, high pressure water boilers in which steam or vapor is generated.

| Pipeline | Piping |

| A pipeline can run over ground, under ground and under water. | The piping facility is mostly above ground with a few underground pipes. |

| Pipe fittings are used in the pipeline only to a limited extent. Usually you see long radius bends and very few other types of fittings in conjunction with a pump station and a valve station. | In the case of piping, you will find a wide range of pipe fittings that are assumed for direction, size, branching, blinding to form a well-defined piping system. |

| Construction drawings for pipelines are called alignment sheets. | Construction drawings for piping are called isometric drawings. |

| Pipelines travel thousands of kilometers to transport fluid from one facility to another | Piping is a complex network of pipe and fittings within the confined premises of the facility or plant. |

| The pipeline system has a small supporting group of valves, pumps and instruments to transport fluid with the highest safety over long distances. | A piping system has an army of supporting equipment for effective operation, such as pumps, valves, filters, vessels, heat exchangers, etc. |

| Design Code for Pipeline is specified in ASME B31.4 and ASME B31.8 | Design Code for Pipeline is specified in ASME B31.3 and ASME B31.1 |

In summary, the differences between pipelines and piping systems stem from their different applications, operating conditions, design regulations and design requirements.

While both are essential to the safety and integrity of fluid transportation systems, the considerations for both are tailored to the specific challenges and environments they face. Wall thicknesses can therefore also differ between a pipeline and a piping system.

Understanding these differences is essential for engineers and designers.

Related Post(s)

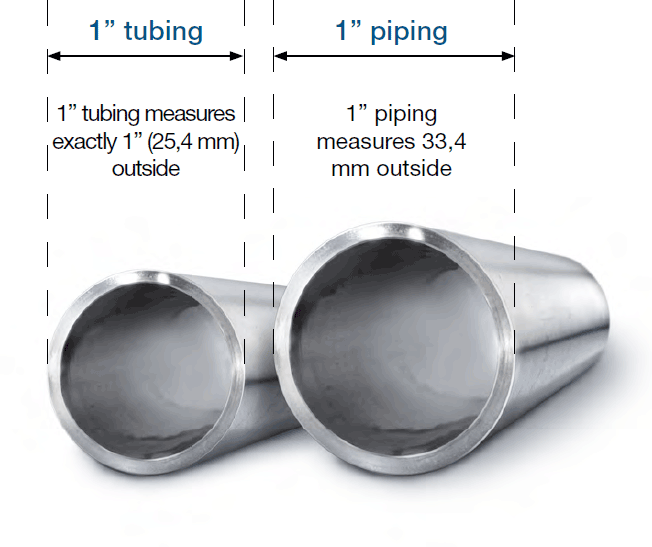

People use the words pipe and tube interchangeably, and they think that both are the same. However, there are significant differences between pipe and tube...