Sealing Pipeline Penetrations

Pipe penetration have been around for hundreds of years. It is believed that sealing of pipe penetrations dates back to the time of the Vikings. The technique usually used was Oakum, in which a braided rope was dipped in tar and then wrapped around the object until the annular space was filled. The method worked and was used for many years.

Today, pipe sealing uses the latest materials and designs to achieve a more consistent, permanent hydrostatic seal.

What is a Pipe Penetration Seal?

When designing a pumping system or renovating, reconfiguring or expanding it, users may be faced with a conduit through a wall or floor. Sealing this conduit so that no substances, gas or liquid leaks out is paramount. Not only can the failure of a gas or watertight seal lead to loss of efficiency or product, but also a safety issue for personnel.

The use of a pipe penetration seal is a reliable tool in such cases. A pipe penetration seal should be chosen for the specifics of the application, taking into account the available materials, temperature range, dimensions and the environment in which it will be installed.

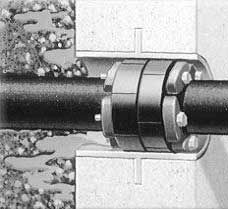

A pipe penetration seal forms a mechanical rubber seal in the annular space between the pipe and the wall opening where the pipe enters the wall. It also forms a seal between the inner pipe and the outer pipe jacket or pipe casing. The seal must be able to work effectively with any electrical pipe, concrete, cast iron, steel, copper or PVC/CPVC (polyvinyl chloride/chlorinated polyvinyl chloride) passing through walls, floors, tanks, pipe casings and vaults.

How it works?

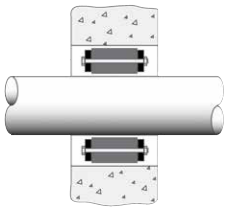

Pipe Seal slides into place

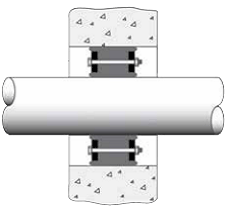

Pipe Seal expands when tightened

Pipe Seal mounted

Pipe Penetration Seal materials

| SEAL MAT. | PRESS PLATES | BOLTS and NUTS | TEMP. RANGE (F) | APPLICATIONS |

| EPDM black | GRP | SZD | -40 to +250 | Suitable for most applications in water, both above ground and direct burial. Provides electrical insulation where cathodic protection is required. |

| EPDM black | GRP | SS (18-8) |

-40 to +250 | Suitable for environments where the corrosion resistance of stainless steel hardware is required. |

| NITRILE | GRP | SZD | -40 to +210 | Resistant to most hydrocarbons, oil, gas, jet fuel, and many solvents. |

| NITRILE | GRP | SS (18-8) |

-40 to +210 | Same as above but with corrosion resistance of stainless steel hardware. |

| SILI CONE |

SZD | SZD | -40 to +400 | Silicone of stainless steel hardware. |

GRP = GLASS REINFORCED PLASTIC

SZD = STEEL ZINC DICHOROMATE

SS = STAINLESS STEEL

Pipe penetrations are suitable for steel pipes with outside diameters from 30mm to over 1000mm and have been subjected to independent overpressure testing, where they have been shown to maintain their stability and integrity in explosions up to 1.35 bar g.

Suppliers of Pipe Penetration Seals:

www.procoproducts.com

www.garlock.com

Remark(s) of the Author...

Oakum is a tar-based fiber that has a long and distinguished history of use in shipbuilding and repair of various marine vessels. Essentially, it is a mixture of fibers coated with tar that can be used to fill small cracks in various types of structures. Oakum with tar was often prepared in the past by people who were in prisons or had to work in workhouses to pay off outstanding debts.