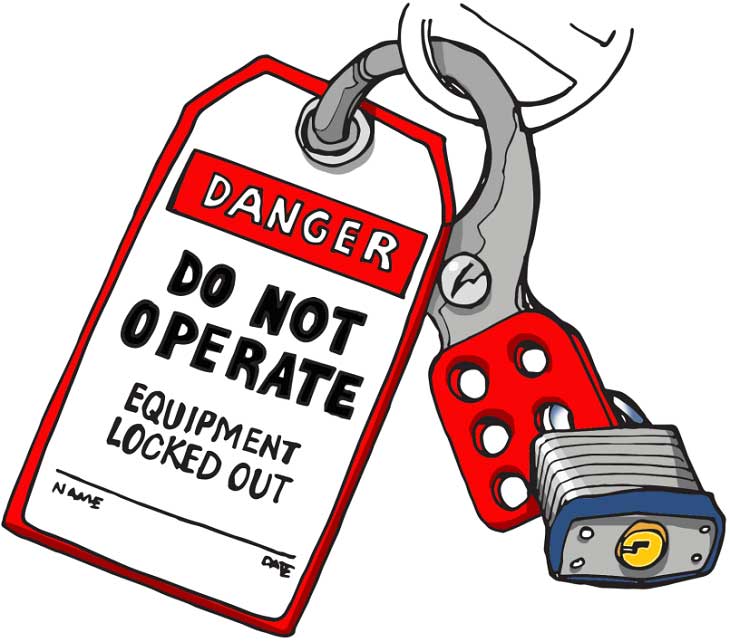

LoTo(To)

LoTo(To) stands for Lockout Tagout (TryOut) and protects an employee by preventing others from using equipment or the switch on the machine during maintenance work or during troubleshooting. It also offers protection against the release of (residual) energy in the equipment or machine.

How does it work?

All power source are turned off/closed and locked in the off position. This could be due to, for example, the locking of an isolation switch or a valve. The employee locks the isolation switch/valve with his own personal padlock (Lockout) so that he/she has control over the energy Reference(s). In addition, a label (Tagout) placed on the padlock to warn others who is responsible for this particular padlock. Because the padlock is personal, no one else can remove someone else's padlock. Therefore can no one accidentally turns on the equipment.

Before the employee goes to the next step, he tests whether the closed maintenance switch/valve is still switched on can be (Tryout). This may of course not be the case.

LoTo(To) is therefore not only there for electrical work but also for mechanical engineering activities. The latter is not always known to everyone.

Lockout, Tagout and Tryout further explained

LOCKOUT

Switch off all possible hazardous energy at isolation points (mains switch, valves, etc.)

Secure all isolation points (isolation switch, shut-off valves, etc.) with a locking system so that they cannot be switched on early and without authorization.

TAGOUT

Applying warning tags to (service switch, valves, etc) for reference.

Tagout does not offer the same guarantee as lockout! Therefore, use all items of the LoTo!

TRYOUT

Make sure that no residual energy is present. Pay particular attention to: mechanical parts of the machine (can it still make its “stroke”)?, is there still energy in the pipeline (hot/chemical liquid or gas)?

Risks: What could happen?

Employees who carry out maintenance or repairs on machines or on/in electrical or mechanical installations do risky work. They open the installation or the machines, parts thereof, which exposes them to other hazards than the employees who operate and/or use the machines or installations.

After all for the operators/users were shielded from the dangers.

For example, employees who carry out maintenance or repairs may come into contact with:

- moving parts

- live parts

- a hazardous substance

The hazards that can occur are also referred to as 'energy Reference(s)'. To prevent injuries and damage to health, the machine or the installation part must be closed prior to the work, (this is also called 'isolating').

All of these overlying risks can result in serious health damage or even death!

What are dangerous energy Reference(s)

The following types of energy source can be distinguished when working on installations/machines:

- Mechanical: moving parts (e.g. conveyor belt, gears, agitator) or materials (e.g. ejected particles, flowing product)

- Electrical (e.g. electrical voltage, static electricity)

- Gravity (e.g. being buried in product)

- Thermal: exposure to high or low temperatures (e.g. radiation, chemical reactions, steam, electrical resistance)

- Liquids and gases under pressure (e.g. in hydraulic systems, pneumatic systems, gas tanks, pressure vessels, steam pipes)

- Chemical: exposure to hazardous substances

- Radiation: exposure to ionizing radiation, non-ionizing radiation, electromagnetic fields

- Biological: exposure to bacteria, fungi and viruses

Follow the steps below of the LoTo(To) procedure to safely enable and disable the machine and/or installation (part).

Release (secure)

| STEP | EXPLANATION |

| 1 | PERMISSION

|

| 2 | SWITCHING AND DISCONNECTING

|

| 3 | PROTECT AGAINST RE-ENABLING

|

| 4 | CHECK

|

| 5 | EARTHING AND SHORT CIRCUIT

|

| 6 | SHIELD ACTIVE PARTS

|

| 7 | TEST

|

Gate Valve Lockout

Gate Valve Lockout

Switching on (recommissioning)

| STEP | EXPLANATION |

| 1 | CHECK

|

| 2 | PERMISSION

|

| 3 | REMOVE PROTECTIONS

|

| 4 | TO CHECK

|

| 5 | SWITCH

|

| 6 | READY FOR USE

|