World's Safest Pipelines

Canada's pipelines are among the safest in the world. By 2020, transmission pipeline operators in Canada will have safely transported more than 1.3 billion barrels of crude oil and more than 4.5 trillion cubic feet of natural gas across the country. There were four crude oil or liquids pipeline incidents in 2020, only one of which was considered significant. There were 15 spills (leaks or similar incidents) from natural gas pipelines, none of which were significant. All spills or releases were cleaned up. (Reference(s).. Canadian Energy Pipelines Association).

Pipeline monitoring, inspections and technology lead to continued improvements in pipeline safety. In Alberta, for example, the total number of pipeline incidents in 2020 was about 40 percent lower than in 2011, while the total length of pipelines increased by 11 percent between 2011 and 2020. (Reference(s).. Alberta Energy Regulator)

A "serious incident" includes one or more of the following: serious injury or fatality, release of more than eight cubic meters (50 barrels) of liquid, accidental ignition or fire, or rupture or breakage of a pipeline.

Pipeline Monitoring and Inspection

From the first day of operation, a pipeline becomes a vital part of Canada's energy needs and its operation is monitored 24 hours a day to identify potential problems before an incident occurs. No one wants a pipeline incident and operators focus on the safety of the environment, the public, pipeline employees and pipelines and associated facilities.

All transmission pipeline operators have a central control room where pipeline operations are monitored 24 hours a day, seven days a week. Sophisticated computer software programs such as those used at airports monitor every aspect of a pipeline's operation. If sensors in the pipeline detect a change, the pipeline can be inspected and shut down if necessary.

At water crossings, pipeline operators monitor the banks and slopes to ensure they remain stable. When changes occur, alarms alert the operator to a possible spill. Pipelines that cross water are equipped on both sides with blocking valves that can be quickly closed to stop flow in the pipeline.

Pipeline operators also conduct integrity inspections, which involves excavating a section of an underground pipeline to clean and examine it. Pipeline operators conduct thousands of excavations each year.

Pipeline Technology

To ensure pipeline safety, Canada’s pipeline operators use sophisticated technology such as..

- Remote sensorstrack changes in pressure, flow rate or temperature

- Hyperspectral imagers (specialized video cameras) are sensitive enough to detect extremely low volumes of evaporated hydrocarbons within a two kilometre radius of the camera

- Aerial light detection and rangingimagery created from airborne laser sensors are used to monitor hazards like landslides, earthquakes and river erosion, which can damage pipelines

- Fiber optic cables installed alongside a new pipeline can help detect tiny leaks by sensing changes of temperature and vibrations caused by flow from a pipe

- SmartBalls, which are placed in the pipeline to travel with the flow and listen for leaks. They have an acoustic data system that can detect small, possibly even pinhole-sized leaks

- Smart membranesthat turn the pipe itself into a sensing device. The membranes are wrapped around pipelines, which can sense leaking fluid and signal operators

- Helicopters and drones are used to view pipelines from the air

- Specially trained dogs are sometimes used to search for leaks, as their ultra-sensitive noses can detect leaks that machines can't

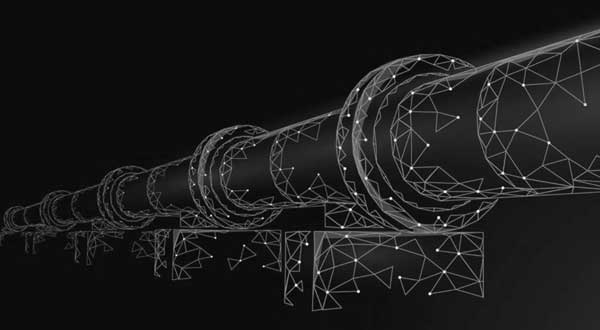

- Smart pigs are sophisticated devices that allow operators to see inside the pipe to find anything out of the ordinary, like minute cracks or signs of corrosion. Smart pigs travel inside a pipeline using ultrasonic technology to spot issues such as metal defects and report any potential issues to the pipeline operator

Using Smart PIGs to Inspect Pipelines

Pipelines are inspected using a device called a pipeline inspection gauge, also known as a smart PIG These highly sophisticated electronic instruments are inserted into the pipeline to scan the inside of the pipe for leaks, cracks, corrosion or other defects that could make the pipeline unsafe.

The development of such inspection tools has led to a whole new world of pipeline safety. Advanced technology better enables the industry to collect and analyze data to effectively prevent incidents. (Reference(s).. Canadian Energy Pipelines Association, 2021).

RESPONDING TO EMERGENCIES

Pipeline emergencies are rare. But to be prepared, every pipeline operator engages in detailed planning, preparation and practice to ensure they are ready for anything. If an incident occurs, pipeline operators work with local and regional emergency response teams to stop the leak, contain the spill and limit impacts.

Detailed emergency response plans are developed to cover any scenario, and rehearsed to ensure smooth execution. Pipeline companies also train and work with municipal emergency services to ensure everyone is ready if needed.

Reference(s) for this article.. www.capp.ca