Expansion Joints (Bellows) in Piping Systems

Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Expansion joints are available in many different shapes and materials. Bellow you will find a short description of Metallic, Rubber and Teflon® joints.

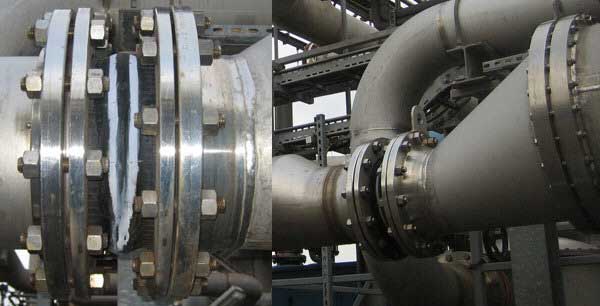

Metallic Expansion Joints

Metallic Expansion Joints are installed in pipe work and duct systems to prevent damage caused by thermal growth, vibration, pressure thrust and other mechanical forces.

There is a wide range of metallic bellows designs in a variety of materials. Options range from the simplest convoluted bellows used in petroleum refineries.

Materials include all types of stainless steels and high grade nickel alloy steels.

Any pipe connecting two points is subjected to numerous types of action which result in stresses on the pipe. Some of the causes of these stresses are..

- internal or external pressure at working temperature

- weight of the pipe it self and the parts supported on it

- movement imposed on pipe sections by external restraints

- thermal expansion

Rubber Expansion Joints

Rubber Expansion Joints are a flexible connector fabricated from natural or synthetic elastomers and fabrics with metallic reinforcements designed to provide stress relief in piping systems due to thermal changes.

When flexibility for this movement cannot be designed into the piping system itself, an expansion joint is the ideal solution. Rubber expansion joints compensate for lateral, torsional and angular movements preventing damage and undue downtime of plant operations.

The special construction of the rubber joints can solve problems like..

- Vibration, Noise, Shock, Corrosion, Abrasion

- Stresses, Load Stress, Equipment Movement

- Vibration, Pressure Pulsation and Movement in a Piping System

Teflon® Expansion Joints

Teflon® Expansion Joints corrosion proof, non-aging with extraordinary flex life and unmatched reliability. The Teflon® expansion joint has a widespread acceptance in the chemical processing industry, piping applications where acids and highly corrosive chemicals are being handled and commercial heating and air conditioning systems as pump connectors and a strategic point throughout a system. They can be used to compensate for..• Movement, Misalignment, Axial Travel • Angular Deflection, and or Vibration in Piping Systems

The Expansion Joint Manufacturers Association, Inc.

The Expansion Joint Manufacturers Association, Inc. is an organization of established manufacturers of metal bellows type expansion joints.

EJMA was founded in 1955 to establish and maintain quality design and manufacturing standards. These Standards combine the knowledge and experience of the association's Technical Committee and are available to assist users, designers, and others in the selection and application of expansion joints for safe and reliable piping and vessel installation.

EJMA members are experienced and knowledgeable manufacturers that have demonstrated many years of reliable service to industry. As reputable manufacturers, EJMA members are the best source for product value, design, and service.

EJMA carries out extensive technical research and testing on many important aspects of expansion joint design and manufacturing.

RUBBER EXPANSION JOINT IN PRACTICE