Hinged Metal Expansion Joints

What are Hinged Metal Expansion Joints?

Hinges are mounted to limit the expansion joint to absorb movements in only one plane in the hinged metal expansion joints. Due to the hinges the expansion joint is not able to absorb axial movement. The hinge is likewise designed to protect the bellow from torsion. These movement limiters reduce the loads from the pressure thrust force and the temperature of the pipeline.

The pressure thrust force from the media is in this way absorbed in the pipeline. The hinges are designed to absorb a larger part of the pressure than the expansion joint is able to absorb. In this way the expansion joint is relieved and at the same time limited to absorb only the movement it is designed for. Further the hinges are designed to support the loads from pipes and connected equipment, wind stresses and other external induced stresses that add external loads to the pipeline.

Expansion joints with hinges are often used in a combination of two or more expansion joints. With this combination the absorption of lateral movement is possible and at the same time each expansion joint can absorb angular rotations. If more hinged expansion joints are installed the distance between them should be as large as possible to ensure the optimum use/absorption of movements.

Hinged Expansion Joints are normally designed to absorb the full pressure thrust of the Expansion Joint and may be designed to support the weight of piping and equipment. Their direction and magnitude must be indicated to the Expansion Joint manufacturer so that the hinges can be adequately designed to withstand these forces.

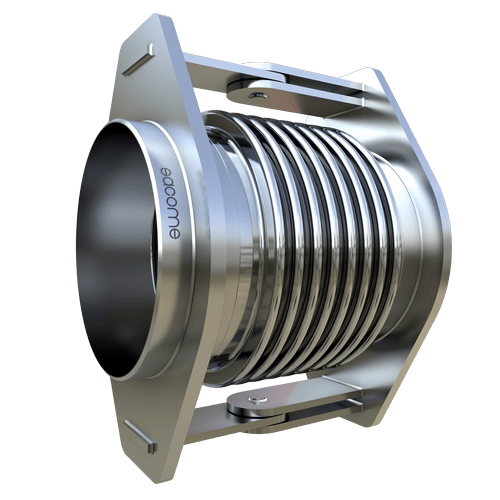

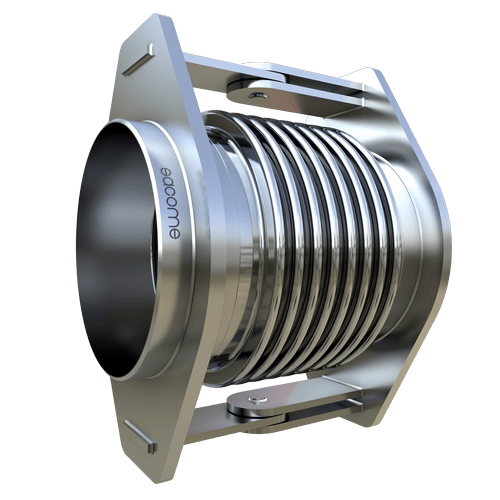

Single Hinged Metal Expansion Joint

The main mission of the Hinged metal expansion joint (simple metal expansion joint for 1-axis for angular movement SSA and SFA) is to absorb angular expansion movements with rotation on a single axis both thermal and mechanical origin.

This hinged expansion joints or simple metal expansion joint for 1-axis is composed of a single bellow of several waves in the form of 'U'.

These waves are made by one or more metal sheets longitudinally welded and shaped hydraulically or mechanically.

Due to its configuration, the designer must bear in mind that these models DO NOT transmit pressure stresses to the fixed points and guides of the piping system.

Metal expansion joint for one axis angular movement with welding ends

Metal expansion joint for one axis angular movement with fixed flanges

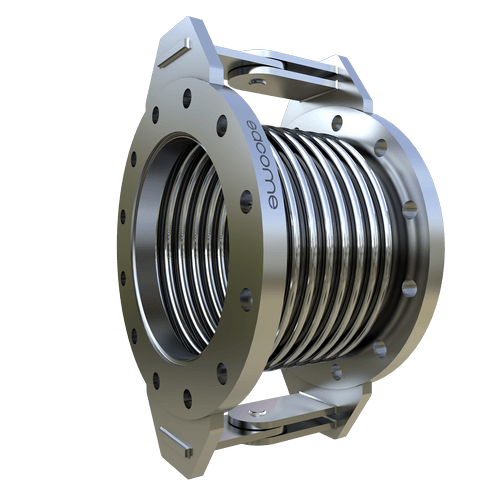

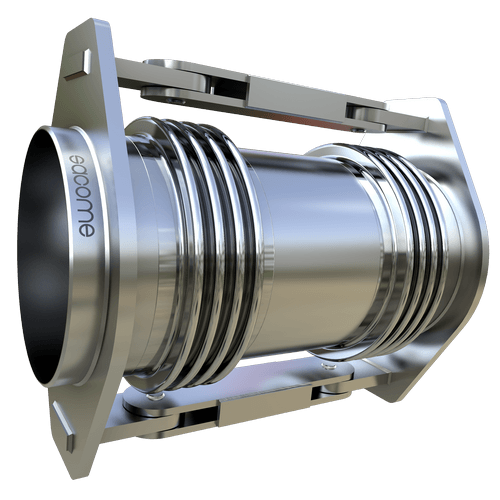

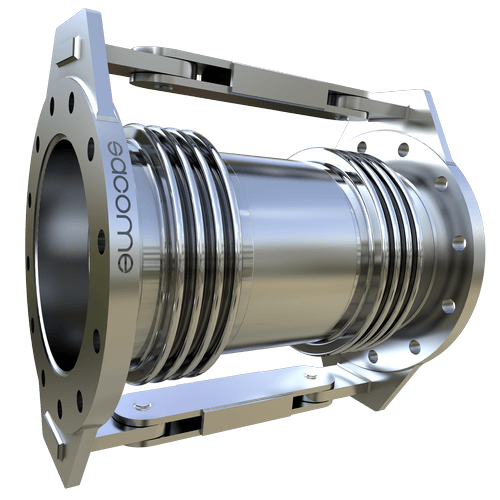

Double Hinged Metal Expansion Joint

The main mission of the double hinged metal expansion joint (universal metal expansion joint for one plane USA and UFA) is to absorb angular and lateral expansion movements with rotation on a single axis both thermal and mechanical origin.

The double hinged metal expansion joint (universal metal expansion joint for one plane) is composed of two bellows of several waves in the form of 'U'. These waves are made by one or more metal sheets longitudinally welded and shaped hydraulically or mechanically.

Due to its configuration, the designer must bear in mind that these models DO NOT transmit pressure stresses to the fixed points and guides of the piping system.

Metal expansion joint for lateral and angular movements in one plane with welding ends

Metal expansion joint for lateral and angular movements in one plane with fixed flanges

Application details for Hinged Metal Expansion Joints

FOR STRAIGHT PIPE RUNS USING MAXIMUM CENTER-TO-CENTER DISTANCE BETWEEN PIPES. A THIRD UNIT CATERS FOR EXPANSION OF OFFSET AND MAINTAINS THE TWO PARALLEL RUNS IN ALIGNMENT. USE THREE SINGLE HINGED BELLOWS.

FOR STRAIGHT RUNS, USING MAXIMUM CENTER-TO-CENTER DISTANCE BETWEEN PIPE CENTERS USE TWO SINGLE HINGE BELLOWS.

FOR TAKING EXPANSION IN TWO DIRECTIONS FROM TWO PIPES AT AN ANGLE GREATER THAN 90, USE THREE SINGLE HINGED BELLOWS.

FOR TAKING UP EXPANSION IN VERY LONG STRAIGHT PIPE RUNS. USE THREE SINGLE HINGED BELLOWS.

FOR TAKING UP EXPANSION IN LONG STRAIGHT PIPE RUNS. USE TWO DOUBLE HINGED BELLOWS WITH DIRECTIONAL ANCHOR AT 'A'.

FOR PIPE BETWEEN TWO VESSELS OR OTHER MACHINERY USE DOUBLE HINGED BELLOWS AND SINGLE HINGED BELLOW.

WHERE THERE IS AVAILABLE OFFSET IN LONG STRAIGHT PIPE RUN, USE DOUBLE HINGED BELLOWS.

FOR TAKING EXPANSION IN TWO DIRECTIONS FROM TWO PIPE RUNS AT 90, USE THREE SINGLE HINGED BELLOWS.

FOR PIPE UP THE SIDE OF A VESSEL, A CROSS OVER BETWEEN TWO VESSELS, OR OTHER MACHINERY, USE DOUBLE HINGED BELLOWS WHERE VERTICAL PIPE IS VERY SHORT.

FOR PIPE BETWEEN TWO VESSELS OR OTHER MACHINERY WHERE LEGS ARE UNEQUAL; THE DIFFERENTIAL VERTICAL EXPANSION BEING COMPENSATED FOR BY MAKING THE BELLOWS UNIT LENGTH EQUAL TO THE DIFFERENCE IN THE VERTICAL LEG LENGTHS. USE DOUBLE HINGED BELLOWS.

Reference(s) for this page.. www.gteek.com and www.sacome.com