Image presentation about

Line Stopping

Size on size line stop fitting with completion plug

1 / 18

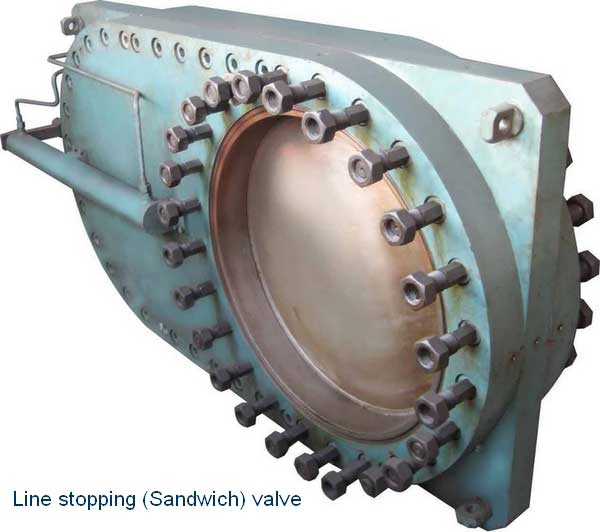

Line stopping (Sandwich) valve

2 / 18

Line stopping machine is installed

3 / 18

Line stop goes down and valve is opened

4 / 18

Line stop is installed

5 / 18

Line stop is installed against the flow direction

6 / 18

Line stop now is in the right position

7 / 18

Vent off product

8 / 18

Mid section can now be cut

9 / 18

Inside the run pipe

10 / 18

After modification/repair..

11 / 18

Upstream head is removed first

12 / 18

Followed by Downstream plugging head

13 / 18

Bypass can now be de-commissioned

14 / 18

Completion plug is lowered through valve into throat of flange

15 / 18

Drive Segment is advanced to secure plug in position of flange

16 / 18

O Ring provides pressure seal

17 / 18

All fittings blanked off - Job complete

18 / 18