Orifice Plates for Flow Measurement and Flow Restriction

Orifice plates are one of the most popular devices for the measurement and control of fluid flow. The shape and manufacturing tolerances of plates used in measurement applications are defined in the international standardization publications of ISO, AGA, ASME and others.

From the formulas and data within these publications, the relationships and values of flow, differential pressure, and plate bore are determined.

In flow control applications, orifice plates are used as restriction devices to regulate fluid flow or reduce the flowing pressure downstream of the orifice plate. The use of a fixed restriction orifice can be beneficial and economic by reducing the demands on other flow system components.

Unlike measurement orifices, the sizing and design of restriction orifices are not defined by standardization organizations. Additionally, restriction orifices, abbreviated "RO", are often exposed to severe flow conditions associated with large pressure reductions and the related fluid conditions caused by liquids flashing to a gas, cavitation, and sonic (choked) flow. In torturous applications, mimicking the design of measurement orifices is not sufficient.

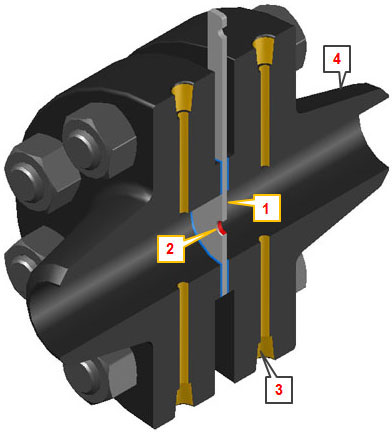

Orifice Plates are normally mounted between a set of Orifice Flanges and are installed in a straight run of smooth pipe to avoid disturbance of flow patterns from fittings and Valves.

Cross section of Orifice assembly

1. Orifice Plate 2. Hole in Plate

3. Tappings 4. Orifice flange

Several types of Orifice Plates

Picture are owned by www.emerson.com

Types of Orifice Plates

Square Edge (Standard) Bore

For the common square edge concentric bore orifice, the bore and bevel is the standard method of limiting the plate edge thickness. Unless otherwise specified, plates will be beveled to the current accepted standards.

Quadrant Edge Bore

The quadrant edge bore is an orifice with the inlet edge rounded. Instead of beveling, the plate is counterbored to the desired edge thickness. The radius of the quartercircle bore is a function of the orifice-to-pipe ratio (d/D). Thickness at the throat is equal to the radius. This bore is specifically designed for viscous fluids such as heavy crudes, syrups, and slurries with Reynolds Numbers below 100,000.

Eccentric Bore

Eccentrically bored orifice plates are plates with the orifice off-center, or eccentric, as opposed to concentric. The bore of the eccentric orifice normally is inscribed in a circle which is 98% of the pipe diameter, so that solids or slurries may pass through. Eccentric orifice plates are used in many industries including heavy and light chemicals, steel, paper, nuclear and petrochemicals.

Segmental Bore

Segmentally bored orifice plates are provided for measurement where solids are entrained in a gas or liquid flow stream. The circular portion of the bore is inscribed within a circle which is normally 98% of the pipe diameter. The segmental opening may be placed either at the top or bottom of the pipe. Industries using these bores include sewage treatment, steel, chemical, water conditioning, paper and petrochemical.

RTJ Type Orifice Plates

General Description

The RTJ type orifice plate incorporates an integral gasket, either oval or octagonal ring, for mounting between ring type joint flanges. It is based on proven technology, has no moving parts and is suitable for high temperature and pressure applications. Orifice plates are recommended for clean liquids, gases and low velocity steam flows.

Plate thicknesses depend on line size and differential pressure, and should be sufficient to prevent the plate from bending under operating conditions. Orifice plates can be made in accordance with customer drawings as required.

RTJ type orifice plates can be supplied complete with ANSI B16.36 orifice flanges.

Paddle Type Orifice Plates

Paddle Orifice Plates are used with raised-face orifice flanges for measurement applications and installed between standard ASME flanges for restriction applications.

The plate and handle are a one-piece seamless design on 1/8-in. thick orifice plates for line sizes 2-inch though 6 inch and ASME classes less than 900. On all other plates, the handle is welded to the plate as standard; one-piece construction is available as an option. The flange ASME class and other standard information is stamped on the handle.

Materials

RTJ type orifice plates may be machined in one piece, or alternatively from two pieces, with an orifice plate screwed onto a carrier ring/gasket.

Standard material grades for orifice plates include 316 Stainless Steel, 304 Stainless Steel, 310 Stainless Steel, Hastelloy® C276, Hastelloy® B3, Duplex Stainless Steel, Super Duplex Stainless Steel, Monel® 400, Carbon Steel, Titanium, Incoloy® 800, Incoloy® 825, Inconel® 600 and Inconel® 625.

Common carrier ring/gasket materials include Stainless Steel and soft iron. To ensure correct sealing when installed between flanges, the hardness of the carrier ring/gasket material is limited to a maximum value, typically 120 for soft iron rings and 160 for Stainless Steel Rings.

Remark(s) of the Author...

Difference between an Orifice Plate and a Restriction Orifice?

An Orifice Plate is used to measure flow, while a Restriction Orifice is used to drop upstream pressure of a system. It is similar to an orifice plate but is thicker. While passing the fluid through thick plate energy is lost in friction and heat resulting considerable pressure drop.

Dimensions of Square Edge Orifice Plates for ASME B16.36 RF Orifice Flanges

Dimensions of Restriction Orifice Plates for ASME B16.5 RF Flanges