What is Plasma Cutting?

Plasma cutting was developed at the end of the 1950s for cutting high-alloy steels and aluminum. It was designed to be used on all metals that, due to their chemical composition, could not be subjected to oxy-fuel cutting. Owing to its extremely high cutting speeds (especially with thin materials) and narrow heat-affected zone, the technique is also used today for cutting non-alloy and low-alloy steels.

Plasma - more than just a state of matter?

Plasma is a high-temperature, electrically conductive gas, comprised of positively and negatively charged particles as well as excited and neutral atoms and molecules.

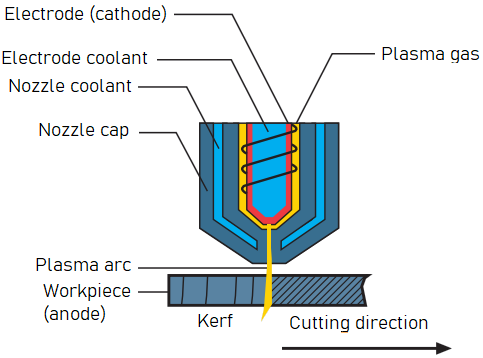

Principle of plasma cutting

Plasma cutting, otherwise known as plasma arc cutting, is a type of melting process where a jet of 20,000°C+ ionized gas melts and expels the material that is cut away from the metal. The transferred arc, which occurs when electricity flows from the non-melting electrode (cathode) to the workpiece (anode), is used to cut electrically conductive materials. This is the most commonly used form of plasma cutting. In the non-transferred mode, the arc occurs between the electrode and the nozzle. Even when using a cutting gas that contains oxygen, the heat effect of the plasma arc prevails. Thus, this method is not considered an oxy-fuel process, but rather a melt cutting method.

Plasma cutting techniques

Plasma cutting techniques are constantly being improved. The main aim of these enhancements is to reduce environmental pollution, increase cutting capacity, and improve cut-edge quality. The ultimate goal is to produce two plane-parallel, even cut surfaces, which require little to no finishing before they are sent on for further processing.

PLASMA BURNING SYSTEMS

Burner cooling

- Water direct

- Water indirect

- Gas cooled

Plasma type

- Dry

- With secondary gas

- With water injection

- Under water

Plasma gas

- Inert

- Oxidising

- Reducing

- Monatonic

- Multiatomic

Electrode type

Needle electrode

Plate electrode

Electrode material

- Tungsten

- Zirconium

- Hafnium

Gases used for plasma cutting

| Material thickness |

Plasma gas | Secondary gas | Comment |

| Structural steel 0.5 to 8 mm |

Oxygen | Oxygen or oxygen nitrogen or nitrogen |

Squareness tolerance similar to laser Smooth, burr-free edges |

| Structural steel 4 to 50 mm |

Oxygen | Oxygen / nitrogen or air or nitrogen |

Up to 25 mm squareness tolerance, similar to laser Smooth cut surfaces Burr-free up to 20 mm |

| High-alloy steel 5 to 45 mm |

Argon / hydrogen / nitrogen |

Nitrogen or nitrogen / hydrogen |

Low squareness tolerance Smooth cuts Burr-free up to 20 mm (1.4301) |

| Aluminum 1 to 6 mm |

Air | Nitrogen or nitrogen / hydrogen |

Nearly vertical cuts Burr-free cuts (AlMg3) Roughness, grainy |

| Aluminum 5 to 40 mm |

Argon / hydrogen / nitrogen |

Nitrogen or nitrogen / hydrogen |

Nearly vertical cuts Burr-free up to 20 mm Roughness, grainy |

Plasma cutting safety

As with all welding and cutting techniques, plasma cutting also requires compliance with the basic industrial safety rules (each country sets its own safety regulations).

Special consideration should be made for the following factors that can occur during manual and machine plasma cutting:

- Electric current

- Smoke, dust and gases

- Noise

- Radiation

- Hot metal spatter

- Environmental influences

Advantages of Plasma Cutting

High Speed Speeds are about 10 times faster than oxy-fuel cutting and 100 times faster than laser cutting!

Simultaneous Use Depending on the series of the machine, they can often be operated simultaneously.

Versatility It can be used on any metal that conducts electricity. It can easily cut high-alloy steel, aluminum, and other materials of medium or high thickness. You can even it on high-strength structural steel.

Portable It can be done by handheld devices, lending it portability that doesn’t come with other methods, but it is only as precise as the hold holding it!

Cost It is less expensive than laser or water-jet cutting.

Disadvantages of Plasma Cutting

- Requires a lot of power

- Not as high quality as laser cutting – this includes issues around inherent bevel or non-perpendicular cuts that vary depending on the side of the "flame", among others

- Restricted to maximum cuts of 180 mm with dry plasma arc cutting and 120 mm underwater

- Loud (can be solved with underwater plasma arc cutting)

Reference(s) for this page:

www.kloecknermetals.com/blog

www.boc.co.nz