Floor gratings

Floor gratings are often seen as a superior alternative to flat surfaces for flooring, walkways, raised platforms and various other industrial applications.

Gratings are lightweight, affordable and low maintenance. It is aesthetically appealing, offering good ventilation and slip resistance. It can be stored and installed relatively easily. And often the material can be reused or recycled, which makes grating more environmentally friendly.

In addition to walkways and raised platforms, floor gratings are used on bridges, commercial-grade catwalks, drain and gully covers, jetties, steps etc.

But there are a number of different options when it comes to choosing your industrial floor gratings. This article describes the most commonly used gratings and types, such as steel floor gratings, aluminium floor gratings and fibreglass reinforced plastic (FRP) floor gratings.

Steel Floor Gratings

Steel is the most popular material for floor grating. It is manufactured using a combination of vertical load bars and horizontal cross rods.

Steel as a material offers excellent durability and resistance to corrosion. It also has great yield and tensile strength.

The most popular two feature a 30mm load bar pitch with either a 100mm or 50mm cross rod pitch.

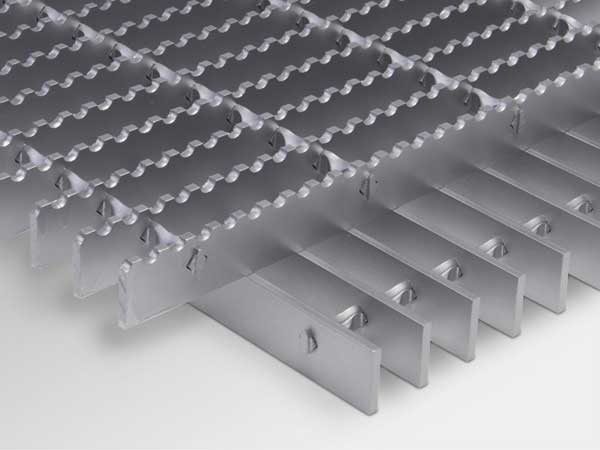

Welded electro-forged grating

Welded electro-forged grating

Welded electro-forged gratings are sturdy grids of bearing bars and crossbars. The bearing bars made from steel strip are not notched or punched. The crossbars of drawn and twisted steel are, contrary to the manufacturing of pressed gratings, pressed into the bearing bars and resistance welded at every joint to ensure high rigidity. These gratings mats form the basis of tailor-made precision gratings with multiple applications. Also, one or two additional cross bars can be added to prevent objects from falling through. To enhance the anti-slip effect for e.g. offshore industry, these gratings are produced with serrated bearing bars.

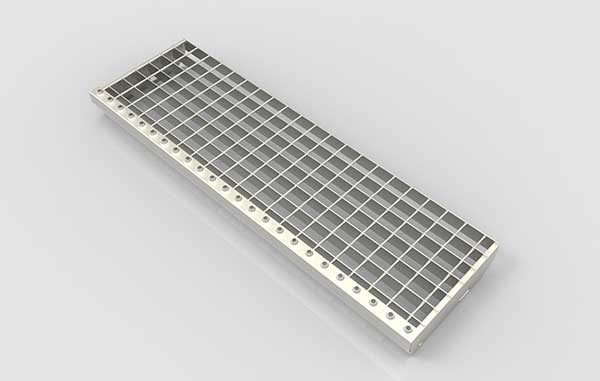

Welded grating stair tread

Welded grating stair tread

Pressed gratings

Pressed gratings

Pressed gratings are sturdy grids of bearing bars and crossbars made from steel strip. The crossbars are automatically pressed into the bearing bars and enclosed by an edge, guaranteeing a rigid panel.

Aluminium Floor Gratings

Aluminium floor gratings are often chosen as a lightweight option. As a material, aluminium is not as strong as steel but it is lighter.

As a result, aluminium floor gratings are popular in industrial environments where weight is a primary consideration.

Aluminium Floor Gratings

Aluminium Floor Gratings

Aluminium is also sometimes regarded as having greater aesthetic appeal than other materials. It is one of the reasons Steve Jobs chose it to make all those iPhones and why it has so many architectural applications.

FRP Floor Gratings

Fibreglass reinforced plastic or FRP floor gratings are replacing traditional floor gratings materials in a number of different industrial applications.

As the name suggests it is not made from metal. Instead FRP gratings are manufactured using either a mould or a method called pultrusion.

Moulded FRP is a mesh of vertical and horizontal layers of fibre rovings and liquid resin combined in a mould. Pultruded FRP takes resin and glass fibre strands and pulls them through a series of steps to create a new composite material.

FRP Floor Grating

FRP Floor Grating

Both methods for manufacturing FRP grating rely on the combined characteristics of glass fibres and polymer resin. The glass fibres provide the final product with its strength and durability, while the polymer resins are resistant to corrosive substances.

What makes FRP particularly appealing in certain situations are its unique properties. Here are some examples:

- FRP floor gratings won't spark if metal objects are accidentally dropped on it. This is an important consideration when working around highly flammable liquids and gases.

- Because it is made from reinforced plastic rather than metal it doesn't conduct electricity, making it a safer option for electrically-hazardous installations.

- It is easier to cut than metal grating. This makes FRP gratings more flexible, allowing for cut-outs for pipework or reshaping for new or complex floor layouts.

- Finally, FRP floor gratings are non-magnetic, which makes it safer in situations that are sensitive to magnetic fields.

FRP Floor Gratings

FRP Floor Gratings

Brief summary

On this page, various grating types are described, but there are so many more types and designs. Specific grating can be manufactured for every application, and many types of clamps are available for securing the gratings.

Reference(s) for this article

staco.eu / locker.com.au