What are Snubber Supports?

Snubbers are restraints used to control the movement of pipelines and equipment during abnormal dynamic conditions, such as shock waves caused by a turbine burst, blowout of safety/relief valves, rapid closure of valves or accidental rupture of pipelines.

Where are they used?

Snubbers are widely used in a variety of applications, including chemical plants, power plants (both conventional and nuclear), refineries and structures such as suspension bridges and tall buildings in earthquake-prone areas.

How do they work?

The design of a snubber allows free thermal movement of components during normal operating conditions. Abnormal conditions cause the snubber to become temporarily rigid (locked state). During the locked state, the snubber transmits the transient force to the ground or to a permanent structure without causing damage to downstream components. Once the transient force stops, the snubber resumes normal operation.

Types of snubbers

There are two types of snubbers.. hydraulic and mechanical snubbers with different types of designs. However, the function of each design is the same - to protect the downstream structure from abnormal shocks. Snubbers are designed for different load levels depending on the extent of seismic activity and the criticality of fluid-induced shocks.

Hydraulic Snubbers

Image.. www.asc-es.com

Image.. www.asc-es.com

This type consists of two concentric cylinders or two parallel cylinders and their respective moving pistons. Both the master cylinder and the compensating cylinders are filled with fluid. The master cylinder and compensation cylinders are connected by speed-limiting valves and a master piston operating in a push or pull mode.

Under normal operating conditions, the valves remain open and the piston can move freely under thermal expansion/contraction of the supported component. When the threshold speed (usually 8 in. per minute) is reached, the valve is activated by shutting off the flow through the valve (also known as valve latch) and the flow through the system temporarily stops.

At that point, the main piston absorbing the shock load stops moving and the load is transmitted to the ground or to a permanent structure, preventing damage to the structure downstream of the snubber. Once the shock wave has passed, the snubber resumes normal operation.

Mechanical Snubbers

Image.. pipingtech.com

Image.. pipingtech.com

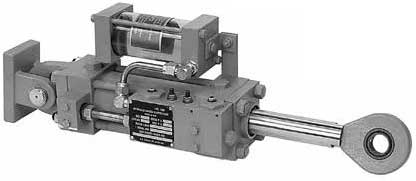

Like hydraulic snubbers, this type of snubber consists of a moving cylinder/rod. However, unlike hydraulic snubbers, mechanical snubbers use mechanical means to provide the limiting force.

Anchor-Darling mechanical snubber

In this type of snubber, the linear motion of the central rod connected to the structural member is converted into an oscillating motion via a spindle mechanism. This oscillatory motion is in turn converted to a rotational motion via a set of gears.

As the linear velocity increases, the inertial force generated in the oscillating spindle and train of rotating gears increases. The extent of this increase depends on the amount of inertial mass and the angular velocities of the gear train, keeping the velocity of the pipe components within the safe limit.

The use of Snubbers (shock absorbers) is preferred in thermally operating piping systems. In a dynamic event, shock absorbers instantaneously form a practically rigid restraint between the protected component and the structure. Resulting dynamic energy can at once be absorbed and harmlessly transferred.