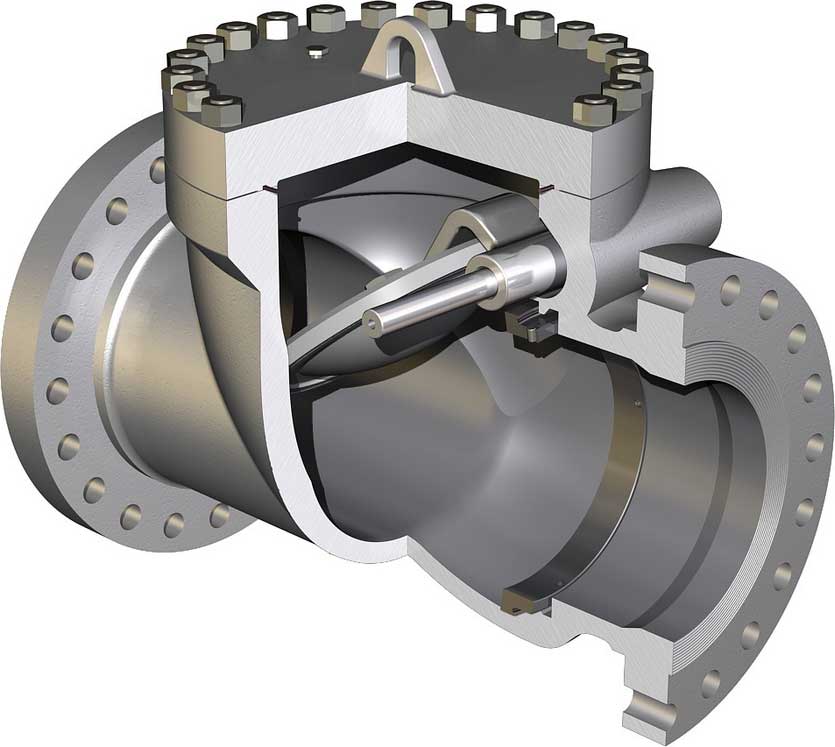

Non-slam check valve

A Non-slam check valve refers to a valve that automatically opens and closes the disc according to the flow of the medium itself to prevent the backflow of the medium, also known as a check valve, one-way valve, counterflow valve and back pressure valve.

Non-slam check valves are non-return valves used to prevent reverse flow of fluid. These valves are also intended to eliminate or reduce water hammer and its associated effects. Non-slam check valves ensure that fluid only flows in one direction. Manufacturers of non-slam check valves produce this valve without a lever or actuator and it works mechanically to prevent the fluid from reversing.

How does a Non Slam Check Valve work?

The mechanical parts open or close themselves depending on the flow and force of the medium. In order to prevent the backflow of the medium, the valve is called a non-slam check valve, and belongs to automatic valves. It is mainly used in pipelines with a unidirectional flow of the medium, and it only allows the medium to flow in one direction.

Types of Non-slam Check Valve

Metal Seated Non-Slam Check Valve

This is a non-slam check valve that is intended for use in high pressure and high temperature applications. This type of check valve has a seat made of metal materials such as carbon steel, stainless steel, ductile iron, brass, and bronze, among other materials. These materials are used to make it suitable for high temperature applications. Moreover, metal seats have high strength, which helps to enhance the high strength against high pressure. Such valves are resistant to corrosive products.

Soft Seated Non-Slam Check Valve

This is a check valve where the seat is made of soft materials such as rubber or plastic. However, the valve body is made of strong metal materials to ensure that the valve can withstand high pressure and impact damage. These materials have low melting temperatures and are therefore recommended for use at temperatures below 60oC. These materials have low strength and can therefore work well in medium and low pressure applications. Soft Seated Non-Slam Check Valves are also used in corrosive applications because they are highly corrosion resistant compared to their metal seated counterparts.

Differences between non-slam and swing check valves

Some types of check valves are specifically designed to cause their disc or flapper to slam shut under certain conditions, such as when fluid flow is reversed. This sudden slam or slamming shut creates a pressure wave in the fluid that reverberates throughout the system and, depending on the exact application, can eventually lead to reduced process efficiency, valve damage, packing joint leaks, and other problems. This unavoidable — but controllable — phenomenon is commonly referred to as a water hammer.

Non-slam check valves are specifically designed for use in these situations. As the name suggests, these valves close without slamming, meaning that no excessive pressure spikes occur. The disc of a non-slam check valve has an internal spring that opposes the opening fluid flow pressure. When the flow of a medium is strong enough, the spring is compressed and the valve opens; the disc is smoothly pushed back to the seating surface in the valve by the spring as the flow decreases and stops, but before the flow direction reverses.

Swing check valves are a more traditional variation. The disc of a swing check valve is attached to the body of the valve by a pivot and hinge arm, without the aid of a spring. Unlike a non-slam check valve, which opens and closes at rates comparable to the pressure of the fluid flow, a swing check valve opens and closes more suddenly, relying on the installation orientation, gravity, and reversing flow to close the valve.

Applications of Non-slam Check Valves

- chemical industry

- oil and gas industry waste water treatment

- food and beverage industry pharmaceutical applications

- water or steam in boiler applications

- water pollution in fresh water supply

Related Post(s)

A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. The disk swings away from the valve-seat to allow flow in the forward direction... Enlarge