What is a Blowout Preventer?

A Blowout Preventer, often known as a BOP, is a critical safety valve device used in high-pressure drilling operations, particularly in the oil and gas industry. It serves as the last line of defense against uncontrolled releases of oil or gas from a well, often referred to as a blowout.

A BOP plays a vital role in preventing environmental disasters, protecting human life, and protecting valuable resources and even the integrity of the drill ship.

Types of blowout preventers and their main components

Annular Preventers

Annular BOPs are designed with a circular, flexible rubber element in their core. When activated, this rubber element squeezes tightly around the drill pipe, forming a tight seal. This design allows annular BOPs to conform to different pipe sizes and shapes, making them versatile for different drilling scenarios.

Ram Preventers

Ram-type BOPs consist of hydraulically operated steel rams that can be closed around the drill pipe to provide a reliable seal. There are two main types: blind rams, which completely close off the wellbore, and pipe rams, which seal around the drill pipe.

Image.. Wikipedia

It is essential to understand these differences between annular and ram BOPs. This information helps drilling teams select the right type based on the requirements of their drilling project.

Control System

The control system is the brain of the BOP, overseeing the hydraulic functions that operate the various components. It allows for remote and manual control, enabling rapid response to emergency situations.

Accumulator Unit

An accumulator unit stores hydraulic fluid under pressure, which provides a fast and efficient response when activating the BOP. This fast response is crucial in emergency situations to prevent a blowout.

Image.. www.researchgate.net

Applications of BOPs in drilling scenarios

Onshore Drilling

Onshore drilling takes place on land, far from the ocean. BOPs play a crucial role in preventing potential blowouts during oil and gas extraction. When drilling onshore, the choice of BOP type is often influenced by factors such as well depth, pressure, and the type of drilling equipment being used. Annular BOPs and ram BOPs can both find applications, depending on the situation.

Offshore Drilling

Offshore drilling takes place beneath the ocean floor. This environment presents unique challenges due to the presence of water, making safety even more important. When drilling offshore, the choice of BOP is typically influenced by factors such as well depth and well complexity. Deepwater drilling, for example, often requires more advanced and robust BOP systems. Subsea BOPs are often used here, with specialized designs to withstand harsh marine conditions.

Unconventional Drilling

In unconventional drilling, such as shale or hydraulic fracturing (fracking), BOPs are also used to ensure the integrity and safety of the well. The choice of BOP type depends on the specific characteristics of the unconventional drilling process and the associated well pressures.

Geographic Considerations

The geographic location of drilling projects can affect BOP selection. For example, drilling in environmentally sensitive areas, such as the Arctic, requires BOPs that are specifically designed to withstand extreme cold and icy conditions.

Understanding these different drilling scenarios and their unique requirements is essential to making the right choice when it comes to BOP selection. It ensures that the safety of personnel, the environment, and the overall success of drilling operations are never compromised. In the following sections, we will delve deeper into the roles that different types of BOPs play in these varying scenarios, highlighting their significance in the world of drilling safety.

Role of BOPs, Maintenance & Safety

Critical Function of BOPs

At BOP Products, we understand that the heart of drilling safety lies within BOPs. These robust devices serve as the last defense against potential disasters. When pressure surges or unexpected challenges arise during drilling, BOPs swing into action, sealing off the well and preventing dangerous blowouts. Their role in maintaining well control cannot be overstated.

Real-Life Success Stories

There are numerous real-world examples where BOPs have saved the day. Take, for instance, the Macondo well blowout in the Gulf of Mexico. Despite the catastrophe, the blowout was eventually controlled and contained, largely thanks to the intervention of BOPs. These success stories underline the indispensable nature of these devices in averting potential disasters.

Regular BOP Maintenance

Ensuring that BOPs are in optimal working condition is paramount. Regular maintenance checks, inspections, and tests are essential to confirm that these devices are ready to perform their life-saving role when called upon. Neglecting maintenance can put drilling operations at risk.

Safety Protocols and Procedures

Drilling teams adhere to strict safety protocols when handling BOPs. This includes rigorous training, detailed procedures, and emergency response plans. These safety measures are in place to protect the well-being of everyone on the rig and to ensure that BOPs are used effectively in crises.

Related Post(s)

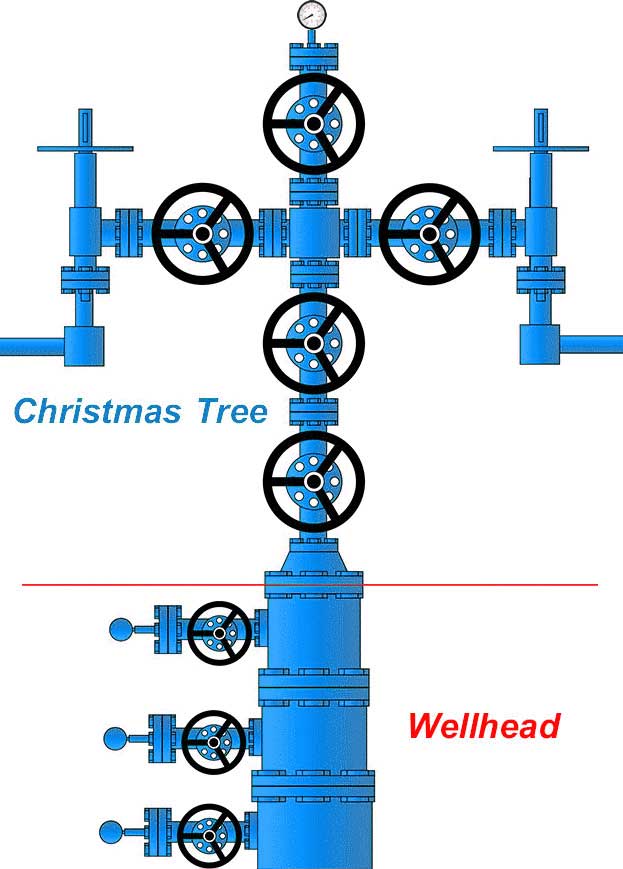

A wellhead is the component on the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. The main purpose of a wellhead is to provide the suspension point and pressure seals for the casing strings running from the bottom of the wellbore to the surface pressure control equipment...