Diverter Valves

Diverter valves are used to divert product flow from one inlet to multiple outlets. They are used on simple gravity (no pressure) applications and high pressure applications. To prevent clogging, leakage and premature wear, it is always critical to divert when no product is flowing through the valve. Changeover valves are ideal for handling dry bulk material in gravity flow, dilute phase or dense phase pneumatic conveying applications.

Types of Diverter Valves (some examples)

Pneumatic Conveying Diverter

In pneumatic conveying systems, diverter valves are used to direct material to multiple destinations or 'take-up points.' They can also be used to direct material from multiple locations to a single location.

In pneumatic conveying systems, diverter valves are installed along the conveying line. The operation of diverter valves in pneumatic conveying systems varies from design to design, but in general there are four main things about them..

- An oscillating tube is mounted on the diverter so that it can automatically move in any direction or position.

- A limit switch ensures correct positioning of the oscillating tube.

- Electric valves control the movement of the oscillating tube, with a pressure gauge measuring and indicating the pressure.

- An inflatable seal is fitted to the head of the oscillating tube to ensure a tight seal between the inner rotating tube and the outer fixed ends

Image.. www.younginds.com

Image.. www.younginds.com

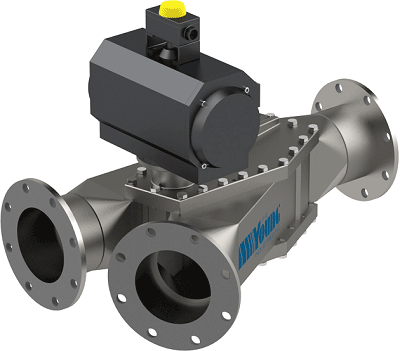

Plug Diverter Valve

Plug Diverters are heavy-duty alternatives to the valve-shaped conveyor changer. They have an internal plug that can rotate 150 degrees to route product from one leg to the other. The round hole in the plug matches the round blow-through ports, making the transition very smooth. The units work well in applications with large particles that can get stuck in a valve-shaped bypass, causing leakage to the dead leg. Because there is no rubber seal, the valve changer is well suited for abrasive products. The plug is rotated as standard with a pneumatic rotary actuator, but can also be supplied with an electric actuator or hand crank.

Image.. www.tbma.com

Image.. www.tbma.com

Scale Diverter Valves

The Scale Diverter Valve is designed to divert dry bulk materials in pneumatic transit to hoppers, bins and silos without the use of pipework bends and supports. The material is diverted to a receiving hopper while air in the return line returns to the storage bin. This valve can be mounted directly on top of the barrel inlet hopper.

Image.. www.schenckprocess.com

Image.. www.schenckprocess.com

Gravity Plug Diverter Valves

The Gravity Plug Diverter is a two-way, demountable gravity diverter valve and is ideal for system installations that require frequent cleaning with minimum downtime. Design allows fast disassembly in installed location and easy access to all product-contact surfaces. Material flow through the valve is unrestricted with no ledges or dead spots. The diverters are manufactured in a range of finish options. The Gravity Plug Diverter diverts gravity fed material to either of two lines by a rotating blade that swings through 120° to fully close off the unused port. This is done with extremely close, machined tolerances between rotating blade and body.

Image.. www.dmnwestinghouse.com

Image.. www.dmnwestinghouse.com