What is a Pinch Valve?

A pinch valve provides a cost-effective and practical solution for controlling the flow of media through a pipeline or other system. It consists of a rubber sleeve, the only wetted part of the entire valve, and prevents fouling of the other parts. Pinch valves have gained great popularity in a number of industries, including food and beverage, medical, pharmaceutical, cement, wastewater treatment and several others, mainly because they clean and move the flowing media under pressure.

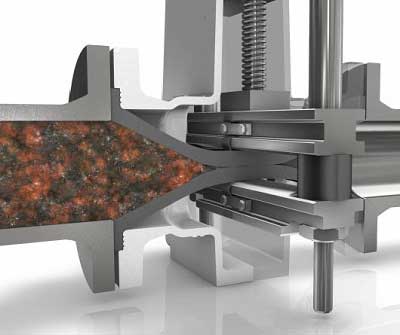

Pinch valve mechanism

In the simplest valve design, pinch valves consist of a flexible elastomer body that impedes fluid flow through the pinch mechanism of the rubber sleeve, which is the main working element. The rubber sleeve is squeezed shut by the application of fluid pressure or mechanically in the body. It is compressed in the center of the valve, with the walls clamped together or squeezed to tightly seal the flow path.

Pinch valves are operated by a linear motion method. In its simplest form, the valve may consist of an elastomeric tube with a pinch mechanism that forms a seal to stop and prevent pinching of the tube. The pinch mechanism is usually performed by a molded rubber tube placed in a housing. This can be done through a simple screw-operated operating principle, where the pinch action is achieved only on one side of the tube. Alternatively, a differential screw may be used to control two squeeze mechanisms that are vertically opposed.

There are also other types of pinch valves that are equipped with a mechanical mechanism and are pressed shut by hydraulic pressure or air injected into the valve body.

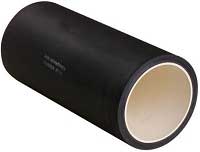

Rubber Pinch Valve Sleeves

The Essential Part to a Pinch Valve

A pinch valve consists of only 3 parts: The body, the end connections and the rubber sleeve. The pinch valve sleeves (also known as rubber diaphragm, bladder, hose, tube, diaphragm, collar, etc.) are the most crucial part of the pinch valve, and are available in a wide variety of rubber materials.

Pinch Valve Sleeve Materials

- Neoprene – 80 degrees c

- Natural Rubber Anti Abrasive – 80 degrees c

- Natural Rubber Food Quality – 80 degrees c

- Natural Rubber High Temp – 90 degrees c

- EPDM / EPDM Food Black – 120 degrees c

- EPDM Food White – 120 degrees c

- Viton – 120 degrees c

- Silicon – 130 degrees c

- Nitrile – 80 degrees c

- Nitrile Food Black – 80 degrees c

- Nitrile Food White – 80 degrees c

- Hypalon – 80 degrees c

- Butyle – 80 degrees c

Natural Rubber Anti Abrasive

Natural Rubber food quality

Silicone for air operated pinches

Pinch Valve vs. Conventional Valves

The Pinch Valve does not have any additional parts that will need replacing every so often such as rings, seals and packing etc, giving the Pinch Valve a very good total cost of ownership. Other advantages of the Pinch Valve include..

- Low weight

- Self cleaning

- Less air consumption

- Low and easy maintenance

- No clogging or dead spots

- Very fast opening/closing times

- Minimal turbulence and friction

- Permanent seal with tight shutoff

- Only one replaceable part (elastomer sleeve)

- Compact, simple, robust and straight through design

- No mechanical parts, bearings, seals or packing required

When referring to conventional types of valves, knife gate sliding valves, butterfly valves, ball valves and diaphragm valves fall into this category. Some engineers do not yet know about the Pinch Valve because it might be new technology to them. However, the Pinch Valve is proven to be the most reliable, cost effective and easy to use valve on the market for some time, in many different applications.

Reference+images.. www.pinch-valves.com